Discover Betec's professional enrobing and coating machines - Your key to perfection in glazing, coating, and enrobing with chocolate.

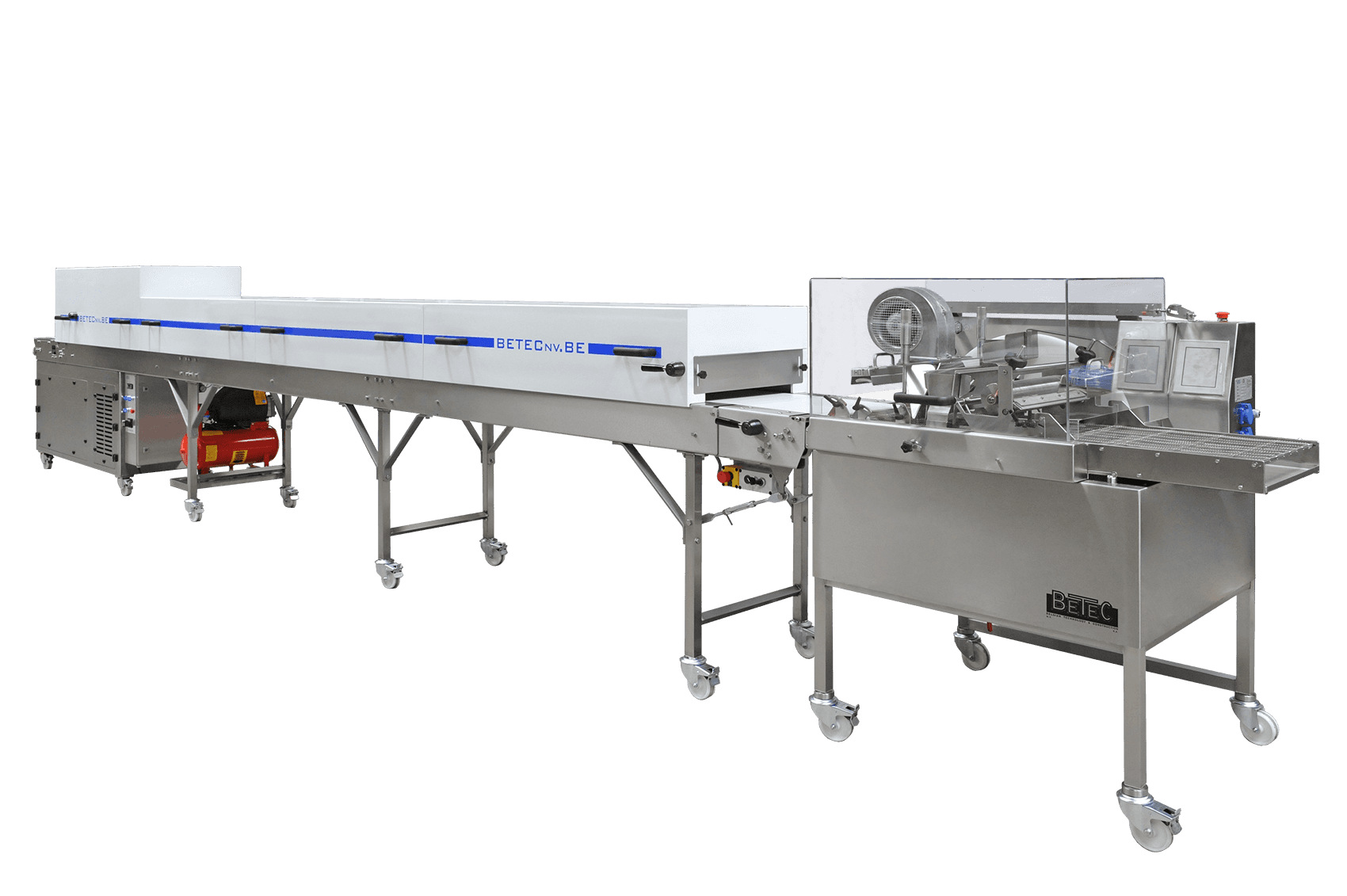

Multifunctional enrobing machines. Betec's enrobing machines stand out for their exceptional craftsmanship and impressive results. When seeking a reliable and efficient glazing and enrobing machine to delicately coat your products with chocolate, compound, fruit coulis, and more, Betec is the choice to make. Our enrobing machines embody a relentless pursuit of perfection, featuring innovative elements that enhance your production process and take your final creations to unparalleled levels of excellence.

The art of enrobing involves the careful application of an attractive and flavorful outer layer.

Our dedication to excellence and innovation

At Betec, we began by constructing medium-sized coating belts for semi-industrial applications, paying attention to all the details required for an industrial, robust, user-friendly, and easy-to-maintain enrobing machine. Unlike other manufacturers who simply enlarge small coating or enrobing machines, at Betec, we have done the opposite. The smaller coating or enrobing machines have been developed from our industrial coating belts, so all the features found in larger industrial models are also present in the smaller models.This ensures that these smaller machines are tailored to meet all your needs from the outset.

Betec enrobing machine: Highlights

- Adjustable chocolate curtain: Adjustable in height and thickness to ensure a flawless coating for your product.

- Adjustable chocolate underbath: Adjustable thickness bottom chocolate layer for a flawless bottom coating of your creation.

- Fan (blower) with adjustable speed: Adjustable blowing force, height, and angle settings for uniform and high-quality coverage.

- Vibrating Mechanism: Adjustable for an optimal distribution of the chocolate.

- Compensation licking roller: Toggleable (On/off) to accommodate different product characteristics

- Heated and handy adjustable rod-detailer: The rotation direction, height, and temperature are adjustable as well, ensuring a precise conclusion to the coating process.

- Enrobing belt, glazing belt or dipping grid under plexiglass cover: The covered and heated workspace creates an ideal working condition. The glazing or coating belt is equipped with one or more adjustable ceramic heating elements, allowing you to create the perfect environment for coating your products. The heated space ensures that the chocolate remains liquid, allowing you to coat each product down to the finest detail without chocolate buildup. An additional advantage of the heated workspace is that it simplifies the startup of your next production run.

For small and medium-sized production runs : Seamless integration with tempering machine:

For smaller and medium-sized applications, we offer coating belts with widths ranging from 240 to 450 mm. These coating, glazing, or enrobing belts can be directly installed on tempering machines such as the MBE series (wheel tempering enrobing machine), MTE series (Mini tempering machine), ATE series (Medium-sized automatic tempering machine), E series (enrobing machines without a temperature unit), and the B series (bottomers, bottom coating coating enrobing machine). What makes these machines unique is that the coating, glazing, or enrobing belt can be effortlessly removed from the base machine, simplifying the cleaning, chocolate switching, and maintenance of the machine.

Industrial applications, seamless integration with or without an external tempering machine :

For industrial purposes, we provide coating belts with widths spanning from 600 to 1600 mm. Tailored to meet these industrial requirements, we have introduced the E-series enrobing machines. These industrial coating, glazing, or enrobing machines come equipped with a retractable coating, glazing, or enrobing belt as a standard feature. The specially designed trolley, used for extending the coating belt, significantly streamlines the cleaning and maintenance processes.

Customized to meet your specific needs

Betec offers tailor-made solutions for coating specific products in the bakery and confectionery sectors, including cookies, donuts, cake, dried fruits (bananas, apples, ...), frozen products (ice cakes, ice pralines, truffles, ...) and more. Our machines can be customized to meet your unique requirements, enabling you to create the perfectly coated product.

Contact Betec - Your partner for coating, glazing, or enrobing systems

Whether you want to coat products with imitation or real chocolate, fruit coulis, or other sugar and fat masses, Betec is here for you. Reach out to us today and discover how we can find the ideal solution together for your coating requirements.

Curious about all the possibilities?

Feel free to browse through our online catalog or contact us for a non-binding quote.

Through the links on the side, you can view our applicable products.

- MBE Series: Wheel coating, glazing, or enrobing machine

- MTE Series: Mini coating, glazing, or enrobing machine with automatic tempering system.

- ATE Series: Medium-sized coating, glazing, or enrobing machine with automatic tempering system.

- E Series: Industrial enrobing machines with an external tempering system.

- B Series: Bottomers, with or without tempering system.

.png&w=1920&q=60)

%20-%20DSC_8946%20C%20.png&w=1920&q=60)

%20-%20DSC_7772%20B%20(1).png&w=1920&q=60)

%20-%20DSC_6803%20I.png&w=1920&q=60)

%20-%20DSC_5658%20G%20.png&w=1920&q=60)

%20-%20DSC_6803%20B(3).png&w=1920&q=60)