Why chocolate tempering is essential for top quality

When making artisan or industrial chocolate figures, pralines, or bars, chocolate tempering plays a crucial role. This process determines how your chocolate looks, feels, and tastes. Without proper tempering, chocolate may have a dull finish, break poorly, and develop fat bloom – making the final product less appealing.

Chocolate tempering – also known as pre-crystallisation – is the precise control of temperature during the melting and cooling phases of chocolate. The goal? To form stable ?(V) crystals (Beta V crystals) in the cocoa butter.

Cocoa butter can crystallise in several different ways. In total, there are six crystal forms (from form I to VI), but only one produces the desired result: the ?(V) structure. This type of crystal gives chocolate its gloss, clean snap, and helps it resist whitening over time. Other crystal forms are less stable and can lead to a dull appearance and a poor mouthfeel.

Proper tempering is therefore essential to consistently achieve that perfect chocolate finish. These ensure a beautiful gloss, a firm texture, a crisp snap and a long shelf life.

The tempering process consists of 3 steps:

- Melting to approx. 45–50°C: all existing crystals are dissolved.

- Cooling to 27–28°C: various types of crystals begin to form.

- Reheating to 31–32°C: only stable type V crystals remain.

Note: these temperatures are indicative. They may vary depending on the type of chocolate. Always consult the technical sheet of your raw materials.

A perfect crystal structure is essential for a high-quality end product – whether you work in artisanal chocolate production or industrial chocolate processing. Well-tempered chocolate retains its shine, has a clean break, and looks visually appealing.

From manual to automatic tempering: your options

Manual tempering – for example on a marble table – requires a lot of time, skill and experience. For larger volumes, this method is often not feasible or cost-effective. That’s why there are various tempering machines that perform the process faster and more precisely.

A manual tempering machine gives you full control over the process, but requires constant supervision and a solid understanding of chocolate behaviour.

If you want consistent quality with minimal manual intervention, an automatic tempering machine is the best choice. It continuously monitors the temperature and adjusts it automatically according to your set value. This guarantees correct crystal formation every time – without the hassle.

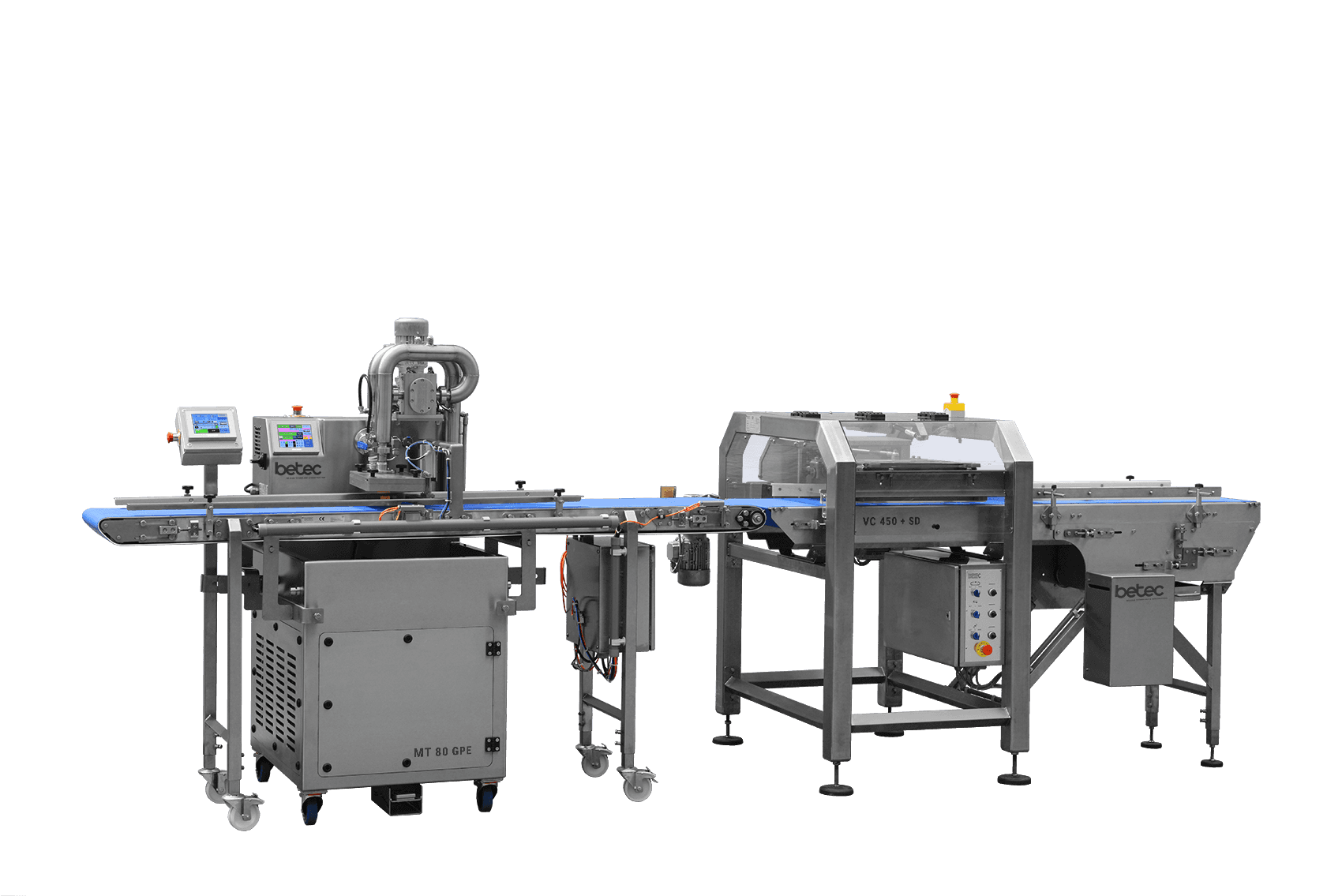

Just like you, Betec strives for perfection. That’s why we developed both manual and automatic tempering machines, each with their own specific advantages.

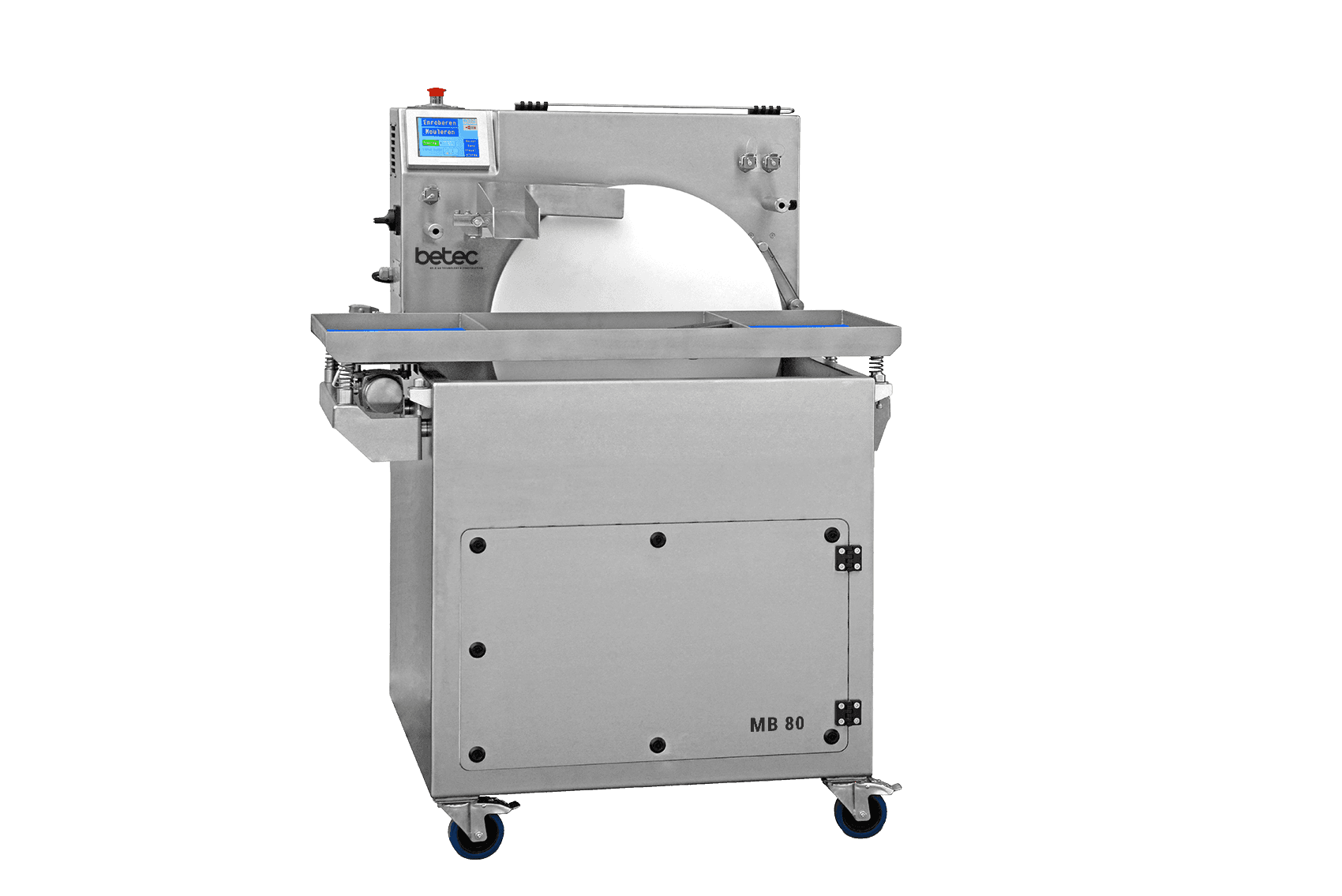

- With the machines from the MB series – also known as wheel machines – you temper chocolate manually. You maintain full control over the process, while the machine remains easy to clean. Ideal for those who combine craftsmanship with flexibility.

- The advanced automatic tempering machines are designed to minimise human error and consistently achieve the perfect chocolate crystal structure. They ensure constant quality and save you valuable time.

Which tempering machine is the right match for your workshop or production line?

Are you working in an artisanal chocolate environment where precision and craftsmanship are key? Then you’ll certainly find the right match within our MB or MT series.

Do you prefer to maintain full control and steer the process manually? Then a manual tempering machine from the MB series (wheel machines) is an excellent choice. Would you rather work semi-automatically, without worrying about temperature settings? Then the user-friendly MT series is the ideal solution.

Do you have medium production capacity and need higher output? Then the AT series offers a powerful and efficient alternative. And for those working with large-scale production lines who want to automatically feed tempered chocolate to downstream machines, the CAT series is the perfect solution.

Whatever your needs, Betec is here to help you find the tempering machine that perfectly matches your production setup.

Precision in your own hands: artisanal tempering with the MB series

The manual tempering machines (wheel machines) from the MB series heat and mix your chocolate automatically, while allowing you to manually control the temperatures. This way, you combine the convenience of a machine with the finesse of artisanal chocolate production.

An extra benefit? Every wheel machine is designed for quick and easy cleaning. This makes them especially convenient when processing multiple types of chocolate with a single machine – the risk of cross-contamination stays minimal, and you save valuable time in your production process.

Professional tempering without worries – discover tempering machines from the MT, AT and CAT series

With an automatic tempering machine, you minimise the risk of human error. Simply set the desired temperatures – the machine does the rest. This not only saves time, but also gives you peace of mind and confidence in every production cycle.

Betec tempering machines work with extreme precision. Thanks to advanced temperature control, the cocoa butter’s crystal structure remains consistently stable. The result? A chocolate product with a perfect gloss, deep colour, and crisp texture – fully in line with the highest quality standards in the industry.

And all that without compromising ease of use. Each machine is equipped with an intuitive touchscreen interface that allows you to easily set, save and recall parameters. You stay in full control, while the machine ensures reliable chocolate temperature regulation.

Depending on your production volume and working method, you can choose from the following series:

- MT (Mini Tempering): Ideal for smaller workshops thanks to its compact size and excellent user-friendliness.

- AT (Automatic Tempering): These mid-sized machines are designed for consistent output and deliver chocolate with unmatched gloss.

Like the MB series, the MT and AT machines can be equipped with a vibration table for moulding or a coating belt to enrobe a wide variety of products with freshly tempered chocolate.

- CAT (Continuous Automatic Tempering): The CAT series is perfect for large-scale lines with a continuous supply of tempered chocolate.

- MATS (Melting and Tempering System): These systems combine melting and tempering in one mobile unit – ideal for flexible production setups.

- TK (Tempering Kettle): TK machines are ideal for batch processing. Melting, tempering and flavour mixing are combined in a single operation.

Ready to take your chocolate process to the next level?

Browse our online catalogue or contact us for a free quote and personalised advice.

Frequently Asked Questions about Tempering Machines (FAQ)

1. What types of chocolate can I temper with a Betec machine?

All Betec tempering machines are suitable for dark chocolate, milk chocolate, white chocolate, and ruby chocolate. Always check the temperature requirements of your specific ingredients.

2. What is the difference between manual and automatic tempering?

In manual tempering, you set the temperature yourself and actively monitor and adjust the process. An automatic tempering machine handles everything independently, keeping the temperature constant based on a preset value.

3. Can I use a tempering machine with a moulding or enrobing line?

Yes. Various models from the MB, MT, and AT series can be equipped with a vibration table or enrobing belt. For larger installations, a CAT tempering machine can supply a continuous flow of tempered chocolate, automatically pumped to the end user.

4. How maintenance-intensive is a tempering machine?

Betec machines are designed with easy maintenance in mind. Wheel machines (MB series) are particularly quick and easy to clean – especially useful when switching between chocolate types. Automatic machines contain pumps and internal piping, making cleaning with water less straightforward. They are usually flushed with new chocolate. Ideally, each chocolate type has its own dedicated tempering machine.

5. What is the warm-up time of a tempering machine?

Warm-up time depends on the model and the amount of chocolate. Most machines reach operating temperature within 20 to 60 minutes. Automatic models manage the full tempering process autonomously.

6. Can I save settings for repeated use?

Absolutely. Betec’s automatic tempering machines come with a touchscreen that allows you to easily configure, save and recall all parameters – enabling fast, efficient and consistent production.

7. How do I know which machine suits my workshop or production setup best?

We’re happy to help you choose the right model. Based on your production volume, level of automation and intended use, we’ll find the ideal solution together.

8. Are the tempering machines compatible with other Betec machines?

Yes. All Betec machines are modular and can be interconnected. Your melting, moulding or enrobing line integrates seamlessly with your tempering machine.

9. What is the lifespan of a Betec tempering machine?

With proper maintenance, our machines last many years. Built from high-quality stainless steel and equipped with premium components, they remain reliable even under intensive use.

Whether you temper manually or automatically – every step counts for a perfect end result.

With a Betec tempering machine, you choose control, quality, and a production process that’s perfect down to the last detail.

%20-%20DSC_8946%20C%20.png&w=1920&q=60)

%20-%20DSC_7772%20B_.png&w=1920&q=60)

%20-%20DSC_5658%20G%20.png&w=1920&q=60)