Betec dosing machines: Precise and efficient dosing for excellent results

Various multifunctional dosing machines : At Betec, we offer a comprehensive range of dosing machines, also known as depositors. These advanced dosing machines are designed to accurately and precisely deposit various liquid masses, including chocolate and various types of fillings, with or without ingredients, quickly and efficiently.

.png)

Precision in dosing leads to less product loss and improves the final product

Volumetric dosing machine, type FM and FMD : For advanced filling (dosing) work

.png)

Both the volumetric dosing machines, types FM and FMD, are designed for dosing various types of fillings. Both dosing machines have their own chain transport, and optionally, an automatic mold destacker can be added. After filling, the mold is vibrated to remove air bubbles and evenly distribute the filling. For even more flexibility, the FMD offers the possibility to integrate two filling stations in tandem in one machine. The abbreviation FM stands for single filling machine, while the abbreviation FMD stands for double filling machine. The FMD is equipped with two filling hoppers in succession, allowing you to dose two different types of fillings consecutively in the mold. As an additional option, you can add a double hopper for each filling station, allowing you to prepare the next filling while still working with the first hopper, significantly increasing production capacity.

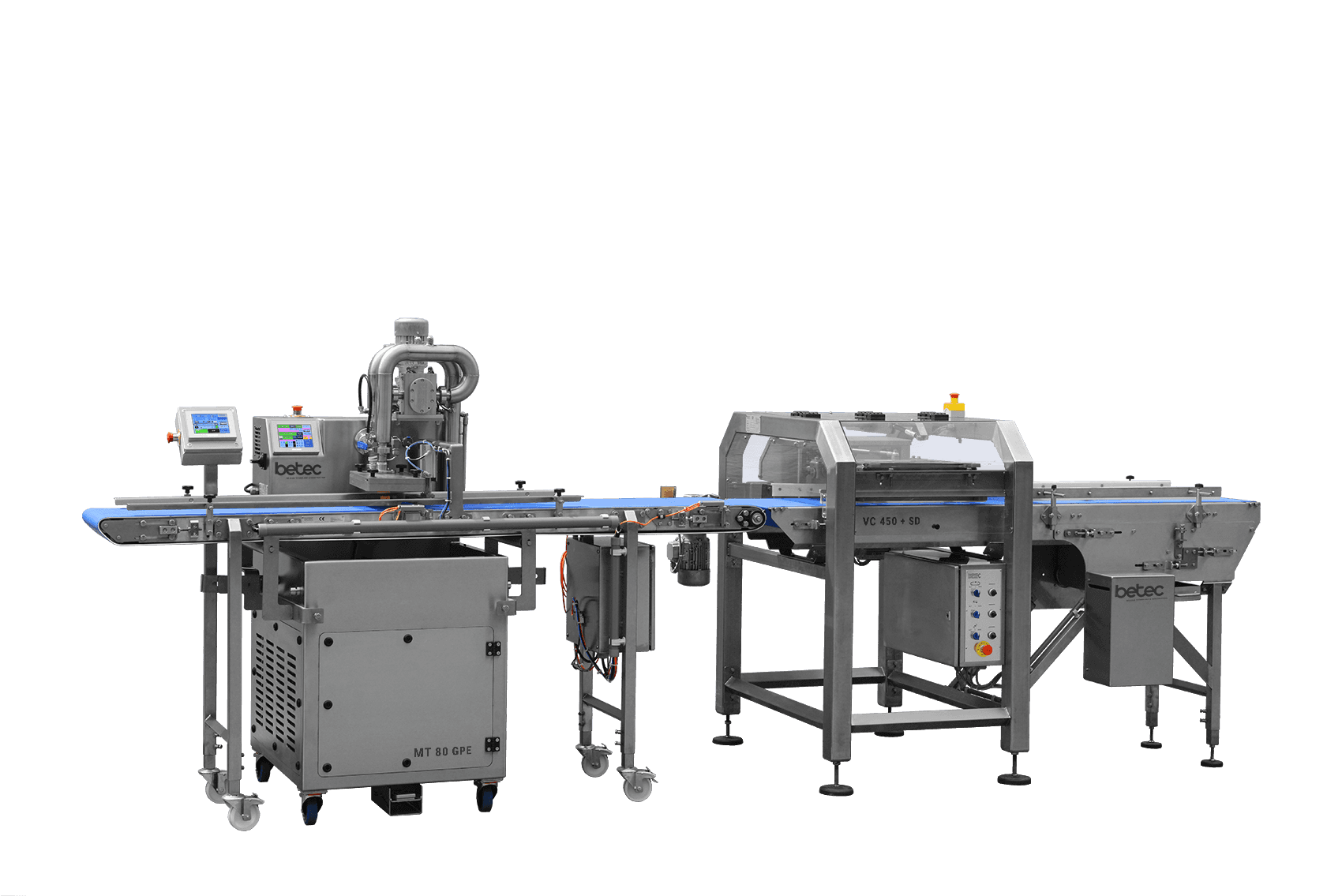

Automatic tempering machines with separate dosing pump

The Betec automatic tempering machines, such as the MT 80 GPE or the MT 80 GPI, are mini tempering machines equipped with a separate dosing pump. In the GPE version, the dosing pump is built on top of the tempering machine, and in the GPI version, the dosing pump is integrated into the tempering machine. Both automatic tempering and dosing machines are ideal for filling polycarbonate molds with tempered chocolate. Both the GPE and GPI versions ensure uniformity, as each recess, cavity, or mold cavity is filled with exactly the same amount of chocolate.

Betec One Shot dosing systems (soft-center dosing machine): Boss 275

.png)

For those who want to go further and produce chocolate products in one step, including products with both chocolate and filling, such as a soft-center filled chocolate product, Betec offers the Boss 275. The Boss 275 stands for Betec One Shot System. This one-shot gearwheel dosing machine is equipped with two buffer hoppers (one for chocolate and one for filling), a set of interchangeable dosing plates, and injects or doses the desired chocolate product - both the chocolate shell and the filling - in one step. This allows effortless and single-step production of chocolate products such as pralines, chocolate bonbons, or chocolate tablets, whether filled with a soft-center filling or not.

CFD volumetric C-frame dosing machine: Specialist in dosing various fillings

.png)

For those working with a molding line and aiming to only inject or dose fillings, the CFD, also known as the Betec C-frame dosing machine, is an excellent choice. The volumetric CFD dosing machines are employed by artisan chocolatiers as well as medium-sized chocolate companies. Thanks to their advanced flexibility, Betec CFD dosing machines are also found in industrial applications. The CFD dosing machines with C-frame are volumetric dosing machines equipped with piston pumps. As a variant, the Betec CFD dosing machines can also be equipped with a gear pump, providing the ability to dose endlessly. The CFD dosing machines can be supplied with their own conveyor belt or can be placed above an existing conveyor belt or cooling tunnel.

Curious about all the possibilities

Browse through our online catalog or contact us for a non-binding quote. Via the following links, you can view our:

- MT/AT GP-series: Automatic tempering machines equipped with an additional dosing pump

- Boss 275: One-shot dosing machine for soft center-filled chocolate products

- CFD-series: C-frame volumetric dosing machines designed for use in combination with a cooling tunnel

- FM-series: Advanced volumetric dosing machines