Chocolate Moulding – From Craftsmanship to Automation

Chocolate moulding, also known as chocolate casting, is the process of pouring liquid, tempered chocolate into moulds to give products like bars, figures or pralines their final shape. Whether you say ‘moulding’ like in Europe, or ‘molding’ the American way – the principle remains the same: chocolate takes its final form through this carefully controlled process.

Although it may seem simple, this process requires precision, timing, and the right conditions. A well-executed moulding step ensures that the chocolate releases cleanly from the mould, achieves a glossy finish, and remains structurally stable.

The Moulding Process in Six Steps

- Preheating the moulds

Cold moulds can cause temperature shocks, leading to uneven crystallisation or a dull surface. Briefly preheating the moulds avoids this risk. As a bonus, any cocoa butter residue becomes liquid and easier to remove.

Note: overly warm moulds can affect the chocolate’s crystal structure, resulting in dull-looking products. - Pouring the chocolate

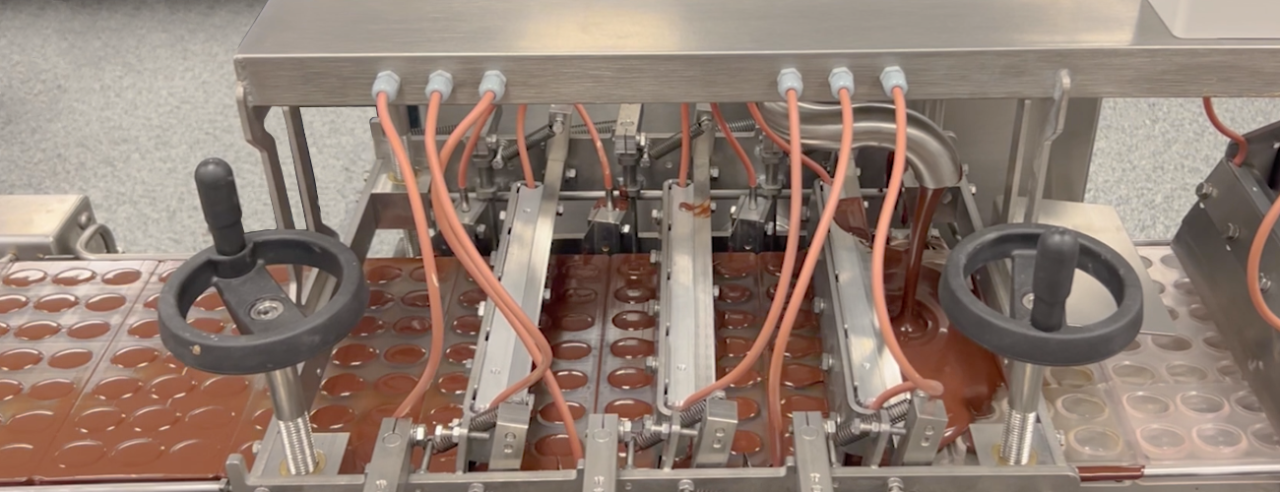

The tempered chocolate is poured into the mould – manually or automatically – using a depositing head or overflow system, depending on the chosen method. - Vibrating the mould (to release air bubbles)

A short vibration lets air bubbles escape and ensures the chocolate spreads evenly. - Scraping or tipping (for hollow shapes)

- For solid moulds, the excess chocolate is scraped off.

- For hollow figures or filled pralines, the mould is briefly turned to create an even shell.

- Filling & closing (for filled pralines)

Once the shell has crystallised, the filling is added. The mould is cooled again until the filling is set, and then the praline is sealed with chocolate. - Cooling and hardening

The filled or solid mould is cooled in a controlled way, resulting in even crystallisation, a shiny surface, and a stable structure.

What to Keep in Mind When Moulding?

- The chocolate must be properly tempered

- The mould must be clean and dry

- The ambient temperature matters (ideally 18–20°C)

- Cooling should not be too fast, to avoid shrinkage or discolouration

With the right technique – and the right machines – you ensure that every piece of chocolate looks professional and tastes perfect.

Chocolate Casting: From Manual Moulding to Automated Depositing

A perfect chocolate creation starts with precision. Crafting irresistible chocolate bars, elegant figures, or refined pralines requires not only craftsmanship, but also consistent execution and the reliable support of the right equipment.

After carefully tempering, one of the most decisive steps in the production process follows: moulding, also known as chocolate casting. This is where each product receives its final shape and visual appeal.

Whether you pour chocolate manually or work with automated systems, Betec offers moulding machines in various configurations tailored to different production needs – from artisanal to industrial.

The Art of Chocolate Casting or Chocolate Moulding

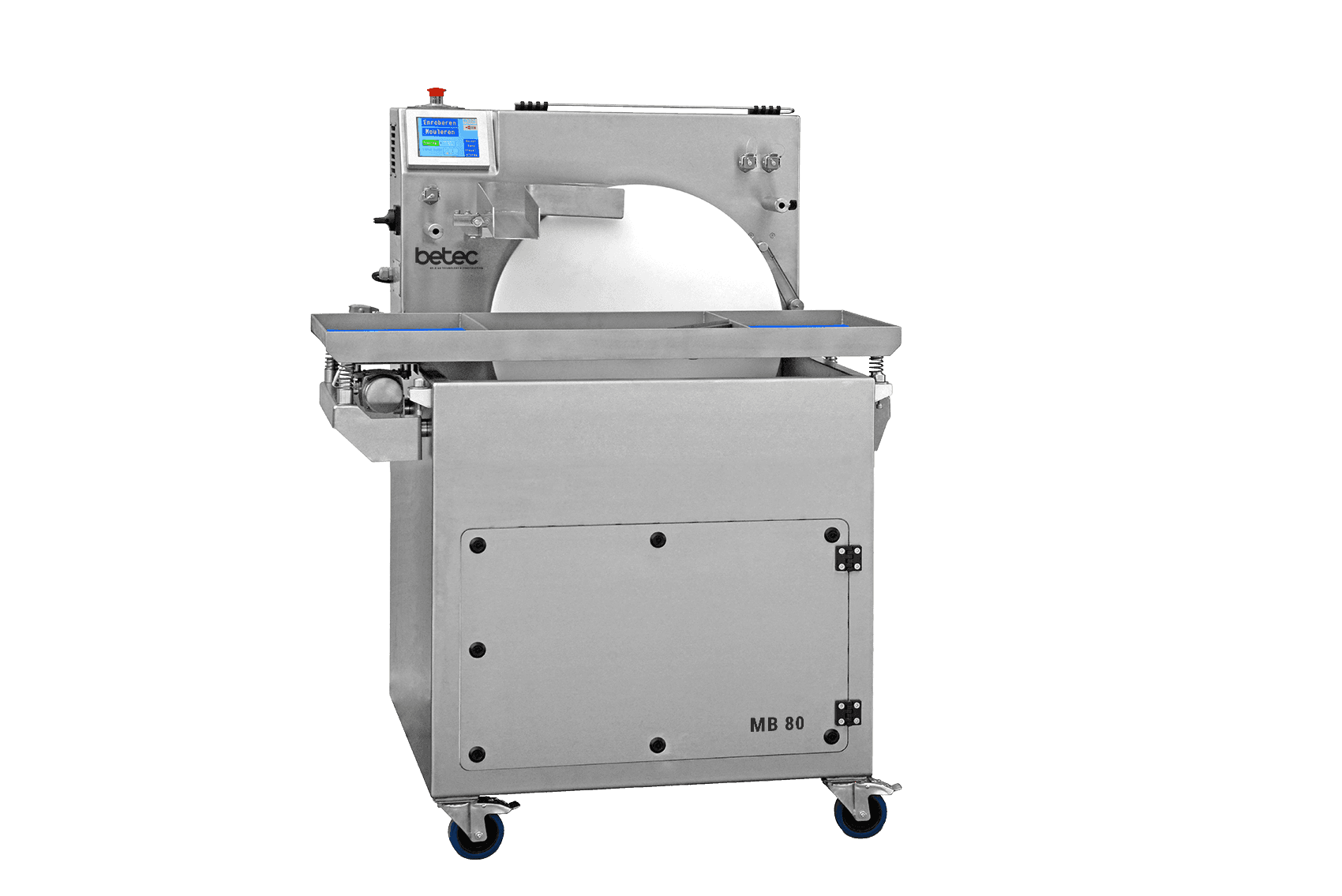

MB Series: Artisanal Control, Simplicity and Reliability in One

.png)

The MB series focuses on manual control, simplicity, and flexibility. These wheel machines are ideal for artisanal moulding work, where you adjust the tempering process yourself.

Thanks to the rotating wheel with scraper, a smooth chocolate flow is created – perfect for filling moulds with fine details or hollow figures. The infinitely adjustable wheel speed allows you to precisely adapt the chocolate flow to your application.

Each machine is equipped with a heated tank that keeps the chocolate temperature stable. The powerful agitator ensures proper mixing, so you always work with a homogeneous chocolate mass.

The MB series is available in four sizes: 15, 35, 80 and 120 kg. All models can also be fitted with a heated vibrating table for even more efficient moulding operations.

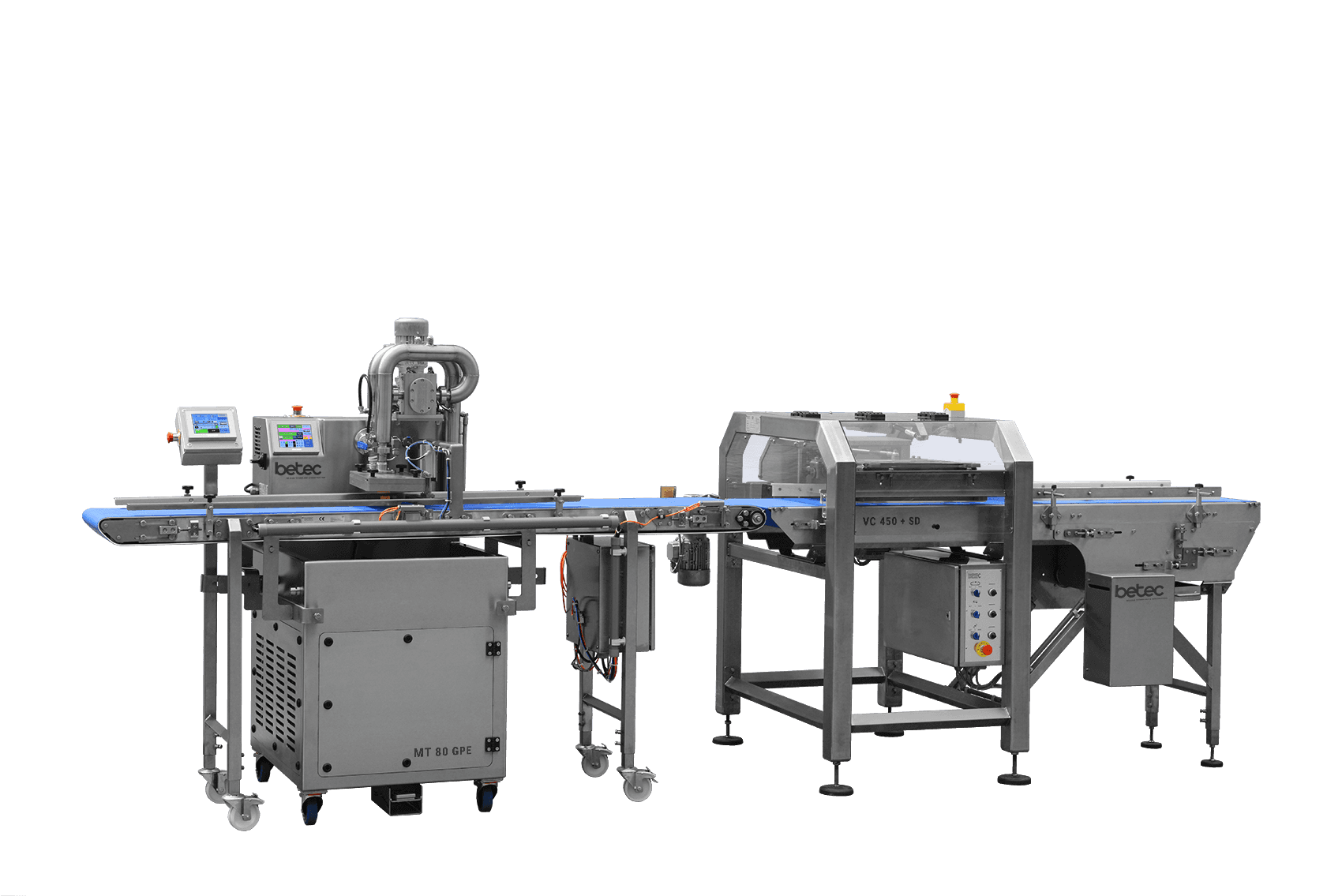

MT & AT Series: Worry-Free Automatic Moulding

The MT and AT series offer a compact and efficient solution for those who want to automatically temper and mould chocolate. Via the intuitive touchscreen, you can easily set the desired parameters, while the machine ensures a consistent and clean chocolate flow into the mould.

The MT series is available in 15, 35 and 80 kg and combines ease of use with excellent moulding results – ideal for smaller production volumes or for those seeking flexibility in a compact setup.

The AT series, available in 80 and 120 kg, is designed for higher production capacities and a more stable tempering process. Thanks to the heated water jacket and advanced tempering system, the temperature is monitored with even greater precision, resulting in chocolate with extra gloss, stability, and longer workability.

The GPE and GPI versions take the moulding process even further thanks to their precision dosing system. Each mould is filled evenly and consistently – perfect for fast, accurate, and consistent production. Suitable for both solid products (such as caraques and bars) and hollow figures.

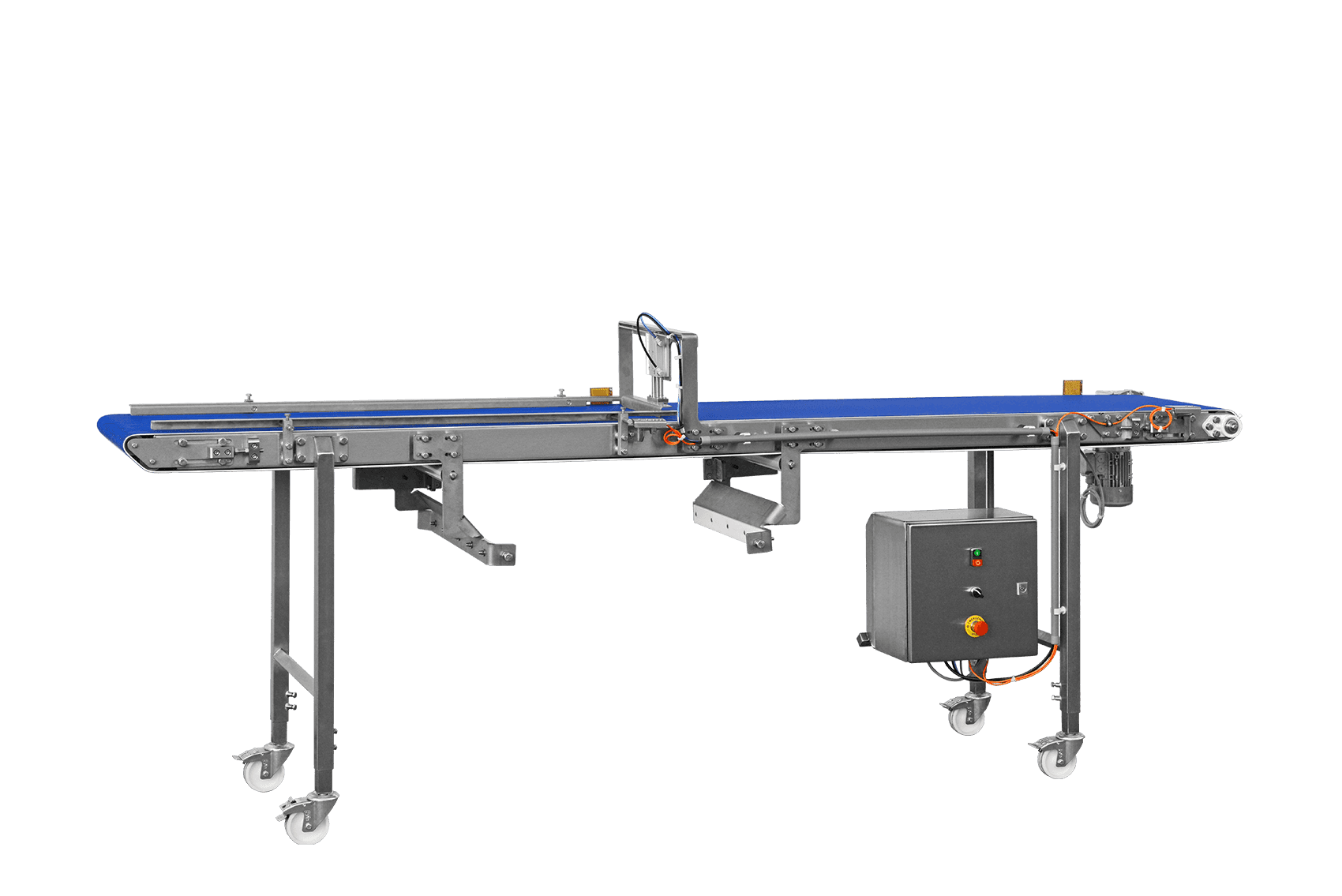

ML & CL Series: Advanced Moulding Lines

Are you producing larger volumes and looking for more automation in your moulding process? Then the CL and ML series offer a well-thought-out semi-automatic solution that combines efficiency with precise control.

As standard, these lines are equipped with:

- automatic mould feeding

- mould preheating

- an integrated chocolate tempering machine

- a chocolate overflow or depositing system

- and a vibration mechanism

Depending on your application, both lines can be configured with additional options such as mould flipping, mould cooling tunnels, demoulding systems, or extra depositing units.

For those looking to scale up gradually, it’s also possible to start with a basic line and later expand with components like a cooling tunnel or demoulding module. This way, your installation grows along with your production.

Want to know more about the different moulding setups? Be sure to visit our information page on moulding lines, where you’ll find a detailed overview of all available configurations and options.

When producing pralines or filled bars, this setup allows you to adjust the shell thickness precisely to match the product. The result: a high-quality finish with maximum repeatability – even for complex shapes or multi-step processes.

Betec: Your Partner for Chocolate Machines

At Betec, we understand that chocolate moulding is more than just technique. It's a precise process where every detail matters – from temperature to timing, mould selection to final finish. That’s why we offer machines for every type of production, from artisanal to industrial.

Curious about all the possibilities?

Browse our online catalogue or contact us for a non-binding quote and personalised advice.

• MB series: Manual tempering machines with wheel

• MT series: Mini tempering and moulding machines

• AT series: Automatic tempering and moulding machines

• CL series: Continuous lines for solid products

• ML series: Moulding line for both solid products and pralines

Frequently Asked Questions about Chocolate Moulding and Casting (FAQ)

1. What is the difference between moulding and casting?

Both terms refer to the same process: pouring liquid, tempered chocolate into a mould to create bars, pralines, or figures. Moulding is the technical term widely used by chocolatiers in Belgium, derived from the French mouler. Casting is a more general term, more common in the Netherlands or outside the chocolate context.

2. Why should I preheat my moulds?

Cold moulds can cause drastic temperature differences, resulting in dull chocolate. Preheating helps avoid thermal shock. An added benefit is that any cocoa butter residue becomes liquid again, which helps maintain shine and ensures the chocolate releases cleanly.

3. Do I always need to use tempered chocolate for moulding?

Yes. Only properly tempered chocolate crystallises well in the mould. This ensures a glossy finish, clean snap, and longer shelf life. Without tempering, you risk fat bloom, dull appearance, and a brittle or uneven structure.

4. What’s better: manual or automatic moulding?

That depends on your production volume and desired level of control.

- Manual moulding gives you full control over the process, ideal for small batches or experimental work.

- Automatic moulding offers consistent quality, higher speed, and fewer human errors – perfect for larger volumes.

5. What does a vibrating table do?

A vibrating table removes air bubbles from the chocolate and helps the mass spread evenly in the mould. This results in a smoother finish without voids or imperfections.

6. Can I make both solid and hollow products with one machine?

Yes. Our 2-in-1 tempering/moulding machines are highly versatile and can handle solid moulds (like bars or discs), hollow products, and filled pralines or bars. In automated production, the ML series offers both options: a chocolate overflow system or depositing head for solid products, and a turning station for creating shells – ideal for filled chocolates such as Easter eggs, pralines, and filled bars.

7. What are common moulding mistakes?

Typical moulding errors include:

- Dull chocolate: often caused by chocolate that’s too warm, moisture, dirty moulds, or new/recently washed moulds.

- Air bubbles: usually due to insufficient or delayed vibration after pouring.

- Difficult demoulding: often the result of short cooling times or poorly tempered chocolate.

Good mould preparation, accurate cooling, and temperature control are key to high-quality results.

8. How can I control the thickness of my praline shells?

In manual moulding, you turn the mould upside down after pouring and vibrating, so some chocolate drains out. What remains forms the shell. The thickness depends on:

- How long you keep the mould upside down – longer time = thinner shell.

- The temperature and crystallisation level – the thicker (and cooler) the chocolate, the more stays on the mould.

- The type of chocolate – white, milk, and dark each behave differently in terms of viscosity and flow.

In automated production (e.g. with the ML series), the shell thickness is defined by chocolate temperature and vibration intensity after the turning station. These parameters are adjustable and reproducible – delivering consistent results batch after batch.

9. Can I store chocolate in the fridge?

Not ideal. It’s best to store chocolate in a cool, dry, dark place between 12 and 20?°C. Refrigerators create condensation, which can lead to fat bloom, loss of shine, and reduced taste – a pity after all your hard work.

10. Does chocolate really help with sports recovery?

Yes – dark chocolate contains compounds that improve oxygen uptake in muscles. A small piece after exercising can be both satisfying and beneficial. Good to know, especially if you’re developing functional or health-focused chocolate products.

11. What’s the largest chocolate bar ever made?

In 2000, Italy broke the world record with a 2-ton bar. Pure chocolate spectacle – not something you’d mould at home, but a great example of what’s possible with passion, technique, and a whole lot of chocolate.

Whether you're working with a single mould or a full moulding line – at Betec, you’ll find the solution that fits your way of working.

From compact machines to advanced moulding systems: we think along with your production needs and deliver reliable technology you can count on every day.

.png&w=1920&q=60)