Essential cooling stage in your production process: precise cooling for consistent quality

Cooling chocolate products may be the final step in your production process, but it’s certainly not the least important.

Although most chocolate workshops today operate in a climate-controlled room, a separate cooling tunnel or professional cooling system still offers many extra advantages. These advanced technologies ensure precise temperature control, stable airflow, and reliable performance – even at higher volumes.

Did you know that natural cooling was once common? Products were stored in cellars or placed near a window to catch a cold breeze. But this often led to quality issues – like dull-looking chocolate or unwanted crystallisation. Fortunately, those improvisations are a thing of the past. Today, you choose efficiency, control and predictable results.

A proper, controlled cooling phase is essential for a beautiful result – especially when working with real chocolate. Even perfectly tempered chocolate can develop faults – like fat bloom or a dull finish – if it’s not cooled correctly.

To avoid that, several professional solutions are available. Think of large cooling cells for full trolleys, or systems like PU-belt cooling tunnels, spiral towers, or compact cooling towers – each tailored to specific production conditions.

Which solution suits you best depends on your product, output speed and available space. While our expertise lies in industrial chocolate processing, we also offer systems for cooling freshly baked waffles, bread, or freezing artisanal ice cream in deep-freeze settings with automated transport.

Whatever your product may be – with the right cooling system, you get the best out of your production. Below we highlight some of the most common chocolate cooling techniques and their applications.

.png)

The key to perfection lies in the proper cooling of your chocolate products

A wide range of cooling systems for various applications

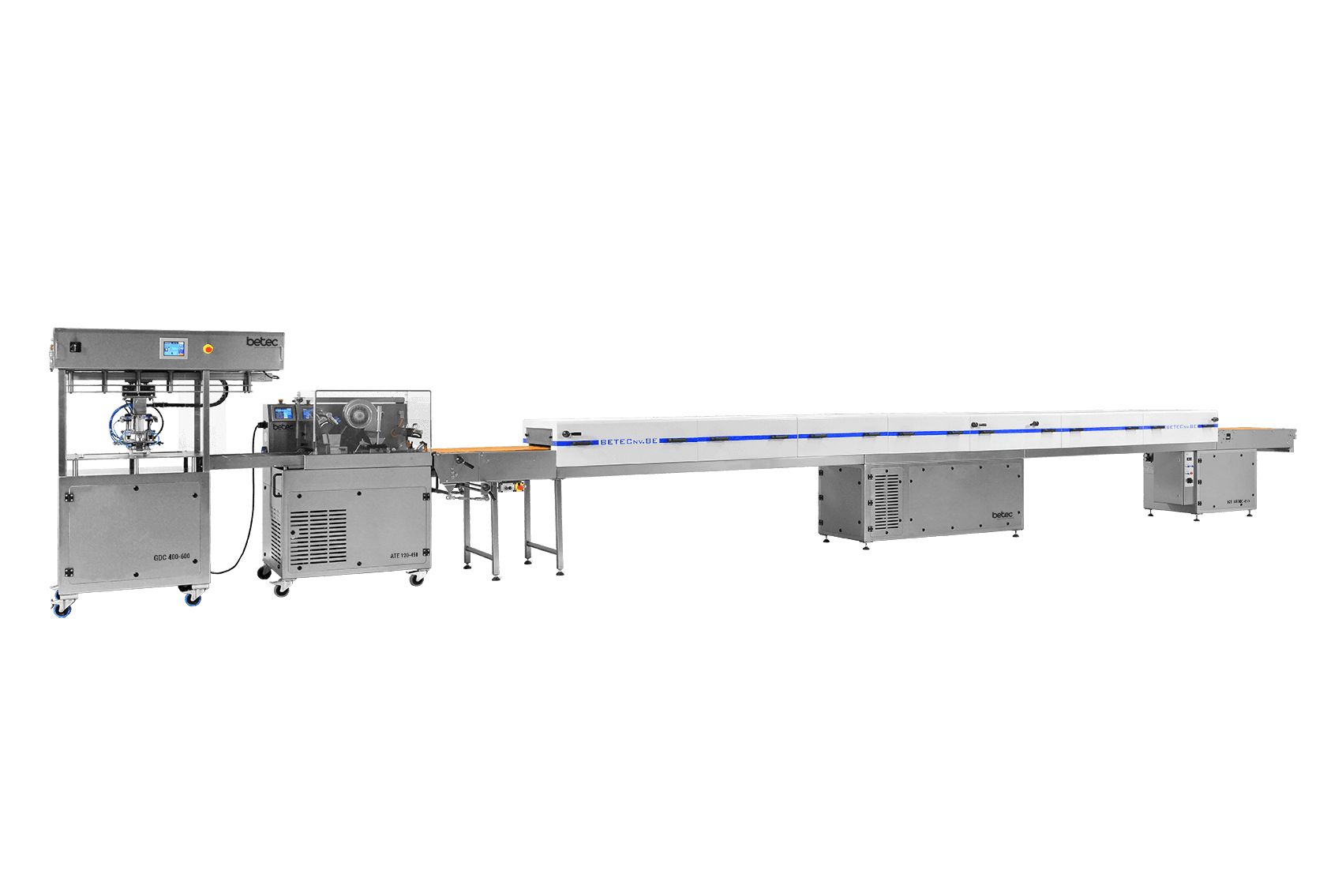

Whether you're cooling chocolate, confectionery, or other food products – selecting the right cooling system makes all the difference. That’s why we design and build cooling tunnels tailored to your production environment and product type.

You can choose between horizontal or vertical cooling tunnels, with or without an integrated cooling unit. Depending on your requirements, the cooling installation can be integrated within the tunnel or placed externally, for example outside the production area.

We work alongside you to deliver a solution that perfectly aligns with your process – both in terms of functionality and hygiene.

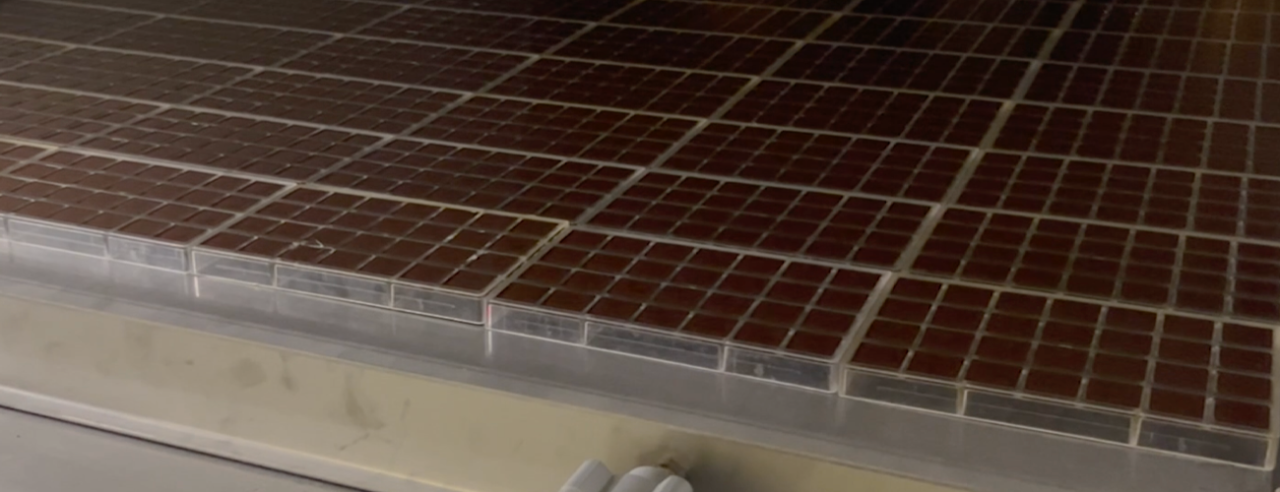

In the chocolate industry, cooling tunnels with a PU conveyor belt are often the preferred choice. These are typically placed behind an enrobing, glazing, or pouring machine, and are ideal for cooling products that have been coated with chocolate or glazed with fruit coulis.

Our tunnels come standard with both convection and radiation cooling. Radiation cooling – also known as indirect cooling – prevents cold air from coming into direct contact with the product, which is crucial for achieving a glossy finish and stable structure, especially when working with real chocolate. With adjustable airflow and convenient dampers, you can easily tailor the cooling process to your product – whether it's chocolate, compound, or coulis.

A well-calibrated cooling tunnel also offers many advantages within your production line:

- Fully automated flow: Products move straight from the enrobing conveyor to the cooling tunnel without manual handling.

- No more paper rolls: Products are transferred directly onto the tunnel belt, reducing waste and cost.

- Ready for packaging: Once cooled, products can be picked up immediately and packed.

When using real chocolate, cooling time is also key. To ensure complete crystallisation of the cocoa butter, products typically remain in the tunnel for 8 to 12 minutes. The tunnel length is adjusted to match your required speed and capacity.

This tunnel is not only a reliable cooling solution, but also an efficient link between chocolate enrobing and packaging.

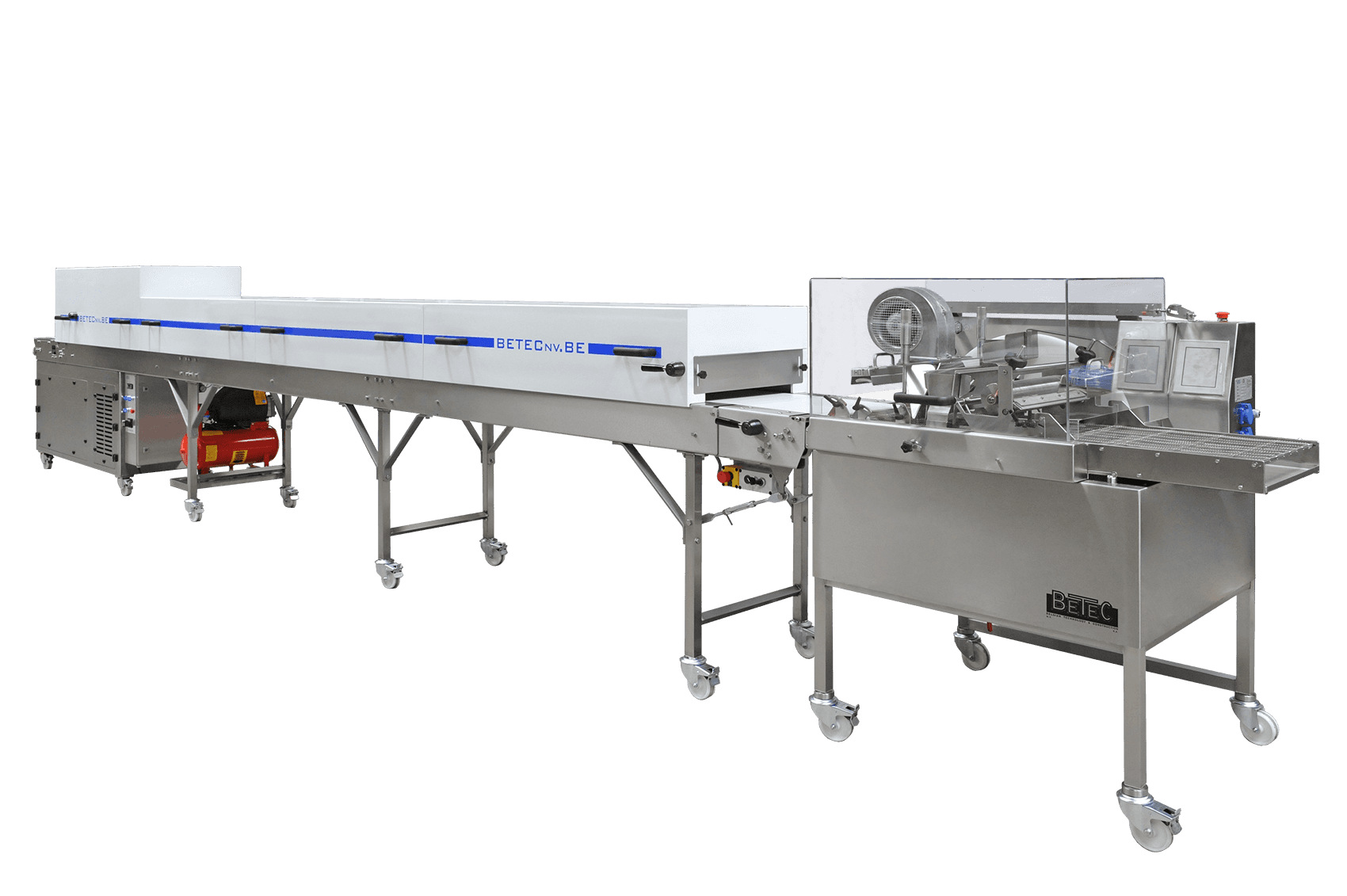

Horizontal cooling tunnel for moulds: more efficiency without time loss

Placing moulds manually on racks and putting them in a cooling room takes time and labour. With our automated cooling tunnel, that’s no longer necessary. You gain in efficiency, consistency, and working comfort.

We build tunnels with step conveyors, where the moulds are automatically distributed across the full width of the tunnel using a loading system. This maximises every centimetre of the cooling capacity and optimises the entire process.

Operation is via an intuitive touchscreen where you can easily view and adjust all parameters at a glance – fully CE-compliant, of course.

We design your tunnel completely tailored to the available space in your workshop. Even in compact environments, we provide a well-thought-out solution – for example with wider but shorter models.

Want to automate even further? Expand the system with options such as:

- automatic infeed and outfeed

- mould twist release system

- automatic demoulding

- mould cleaning

- return systems

- and automated mould or product transport

Each cooling tunnel is built to your specific needs: from a practical basic version to a fully automatic line. Always tailored to your production, your space, and your budget.

Vertical mould cooling tunnel / Ladder cooling:

In addition to horizontal cooling tunnels, there are also vertical solutions – ideal for specific product types such as filled moulds. A ladder rack inside a cooling chamber – also known as a paternoster system – offers an extremely efficient solution for the controlled cooling of filled chocolate moulds. The moulds, freshly filled with tempered, still-liquid chocolate, are automatically fed into the vertical mould cooling tunnel.

Thanks to the smart design and advanced operating principle, there is always sufficient space around the moulds. This ensures ideal heat transfer and perfectly even cooling.

Inside, the polycarbonate moulds gradually move from the infeed to the outfeed while being cooled and crystallised in a refrigerated environment. At the end of the cycle, the moulds are immediately ready for demoulding – no extra waiting time required.

Ladder cooling systems are also available as tailor-made solutions: the individual racks can be placed in separately cooled zones. This allows for multi-stage cooling with distinct temperature settings. The result is a significantly faster cooling process, without compromising the gloss or quality of the chocolate.

Ideal for those seeking maximum control over every detail of the production process – especially when working with polycarbonate moulds.

Key advantages of ladder cooling (paternoster system):

- Efficient use of space: vertical setup ensures maximum capacity in limited floor space

- Perfect heat transfer: free space around each mould guarantees even, controlled cooling

- Faster cooling cycles: multi-zone cooling allows different phases to occur simultaneously

- Optimal crystallisation: results in beautiful gloss and stable chocolate structure

- Immediate demoulding: moulds are ready for the next step without additional waiting

- Custom-built: fully adapted to your products, capacity, and available space

Cooling spirals and spiral freezing towers with perforated modular conveyors

Spiral towers are ideal for the controlled cooling of coated pastries, waffles, ready meals and more.

If you apply a chocolate top coating to items like cookies or waffles (without coating the bottom), this cooling setup is ideal. Since the underside remains free of chocolate, the conveyor stays clean and tidy.

The spiral systems use convection cooling, where cold air is blown directly onto or beneath the product. This ensures rapid heat extraction and high cooling capacity.

Spiral cooling towers can be configured as:

- a refrigerated or frozen unit, for controlled temperatures down to -30°C,

- or without a chamber, cooling the product using ambient air.

Thanks to their compact footprint and continuous flow, spiral belts are ideal for industrial applications. They are widely used in bakeries for cooling waffles, pastries, and bread, and in the ice cream industry for freezing freshly prepared ice cream.

.png)

Horizontal cooling tunnel or spiral tower: which solution suits your production?

The main difference between a horizontal cooling tunnel and a spiral tower lies in the available space. A spiral tower with modular belt is built vertically, allowing you to achieve a longer conveyor length on a smaller floor surface. Please note: to install a spiral tower, sufficient ceiling height is required in your production environment.

The belt in a spiral tower moves slightly upward or downward – like a spiral staircase – so the products always rest at a slight angle.

For products that need to stay perfectly flat, such as moulded forms, a ladder cooler or a horizontal cooling tunnel (when space permits) is the better choice.

A spiral tower is especially suitable when:

- You have limited floor space,

- Sufficient vertical height is available,

- And your products can tolerate a slight incline during cooling.

Explore more solutions in our online catalog or contact us directly for a non-binding quote tailored to your needs. Together we’ll find the cooling solution that perfectly matches your production process.

Frequently Asked Questions about Cooling Chocolate Products (FAQ)

1. Why is controlled cooling so important for real chocolate?

The structure and shine of real chocolate depend heavily on proper crystallisation of the cocoa butter. During cooling, the crystals must form in a controlled way to avoid fat bloom or discolouration. A proper cooling curve ensures gloss, a firm snap, and extended shelf life.

2. When should you choose a horizontal cooling tunnel and when a ladder cooler?

Choose a horizontal tunnel when floor space is available and your products must remain perfectly flat (e.g. molded chocolates). Ladder cooling is ideal when floor space is limited but vertical height is available. If products can tolerate a slight incline (e.g. waffles, cookies, bread, ice cream), a spiral tower is a great option. Spiral towers can be installed with or without a cold room.

3. What’s the difference between convection and radiation cooling?

Convection: cold air is actively blown onto the product – fast and powerful, suitable for sturdy items. Radiation (indirect cooling): cold air circulates around the product without direct contact – more gentle, ideal for delicate chocolate items. Most Betec tunnels allow you to switch between both via a valve.

4. What if my product needs to stay completely flat during cooling?

Use a horizontal tunnel or vertical ladder cooler (paternoster). These systems ensure the molds stay level throughout. Ladder cooling is especially suitable for filled or hand-cast chocolates. Each mold circulates vertically and cools evenly in a controlled climate.

5. What happens if chocolate is cooled too quickly?

Uncontrolled cooling leads to irregular cocoa butter crystallisation. This can cause the shell of filled products to crack and fillings to leak. It also reduces gloss. A gradual cool-down is just as important as tempering.

6. What’s the ideal temperature for cooling chocolate?

Between 8–12?°C for real chocolate, depending on layer thickness and product type. Colder temps (down to 5?°C or lower) are suitable for fruit coulis or compound chocolate, but too cold increases condensation risk and reduces shine.

7. Can spiral towers be used in cold environments?

Yes. Spiral towers are often used in freezing applications, such as freezing fresh ice cream at -30?°C. The airflow helps maintain smooth structure and limits crystal formation.

8. What is the benefit of a water-cooled bottom plate in a cooling tunnel?

It increases total cooling capacity, especially under the product. Heat is removed more efficiently, and the top layer remains undamaged – ideal for thicker products or fast cycles.

9. Why opt for multiple cooling zones in a single tunnel or tower?

Multiple zones allow for gradual cooling.

- First zone: gentle cool-down to avoid thermal shock.

- Second zone: more intense cooling to complete crystallisation.

This improves quality and enables seamless demolding or packaging.

10. Can I adjust the conveyor speed myself?

Yes. Most tunnels and towers have a touchscreen interface to control belt speed. This gives flexibility to adapt cooling time to product type and production flow. Especially useful when changing chocolate types or switching between batches.

Cooled to the Core, Engineered to Perfection

Every step in your production counts – and proper cooling is what makes the difference between good and exceptional. Whether you're producing pralines, bars, waffles or ice cream: a well-designed cooling solution enhances quality, reduces error risk, and boosts efficiency.

At Betec, we combine technical expertise with hands-on experience to build systems that truly work – for your products and your space.

![BETEC KT 240[0.5+5.5+0.8]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto-11_KT-240(0%2C5%2B5%2B0%2C7)-M1-M8.png&w=1920&q=60)

%20-%20DSC_8946%20C%20.png&w=1920&q=60)

%20-%20DSC_7772%20B_.png&w=1920&q=60)

![BETEC KT 450[1.8+6+1]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto%2048_KT%20400%20-%20PHOTO-2019-10-21-19-38-17%20C%20.png&w=1920&q=60)

.png&w=1920&q=60)

.png&w=1920&q=60)

![BETEC KT 600[1,5+12+1,5]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto%2071_KT%20600(1%2C5%2B12%2B1%2C5)-close%20-%20DSC_4273%20G%20.png&w=1920&q=60)

![BETEC KT 1050[1+18+1]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto%2072_KT%201050(1%2B18%2B1)-open%20-%20Photo-2018-05-25-17-10-32%20B_.png&w=1920&q=60)