Betec Deco-Magic: Decorating Chocolate with Precision and Creativity

Decoration for Chocolate Products: more visual appeal with minimal effort. Long before the advent of modern decorating machines, chocolatiers and pastry chefs relied on craftsmanship and creativity to finish pralines, cakes, and other treats. Fine lines of tempered chocolate were applied using a piping bag or cornet, products were dipped by hand and worked with forks or combs, and decorations like hazelnuts, candied sugar, or fruit were carefully placed one by one.

Decoration for Chocolate Products: More Visual Appeal with Minimal Effort

In pastry making, it was much the same: piping bags, stencils, and powdered sugar created unique patterns and elegant finishes on each treat. These techniques often produced stunning results but were time-consuming and hard to reproduce. Today, that same refined look can be perfectly combined with efficiency and consistency, thanks to automated decorating systems. A simple praline, bar, or pastry becomes a true eye-catcher in a single movement with the right decoration.

On this page, you’ll discover all the possibilities: from granulate sprinklers and powder dispensers to machines for drawing artistic chocolate lines. We discuss the pros, cons, and levels of automation for each technique.

With a Betec decorating machine, you get a result that makes all the difference — attractive, hygienic, and reproducible.

.png)

Discover the magic of decoration – from delicate chocolate lines to colourful granulate finishes that make your products visually stand out. At Betec, we believe that a thoughtful finish makes all the difference on the shelf. Whether you opt for a subtle chocolate drizzle or a decorative topping with nuts, sugar, or crunch, our decorating machines help you take each product to the next level.

Read more below about the different techniques and discover which decorating solution best fits your production environment.

Granulate Decorating Machines: For Crunchy Finishes

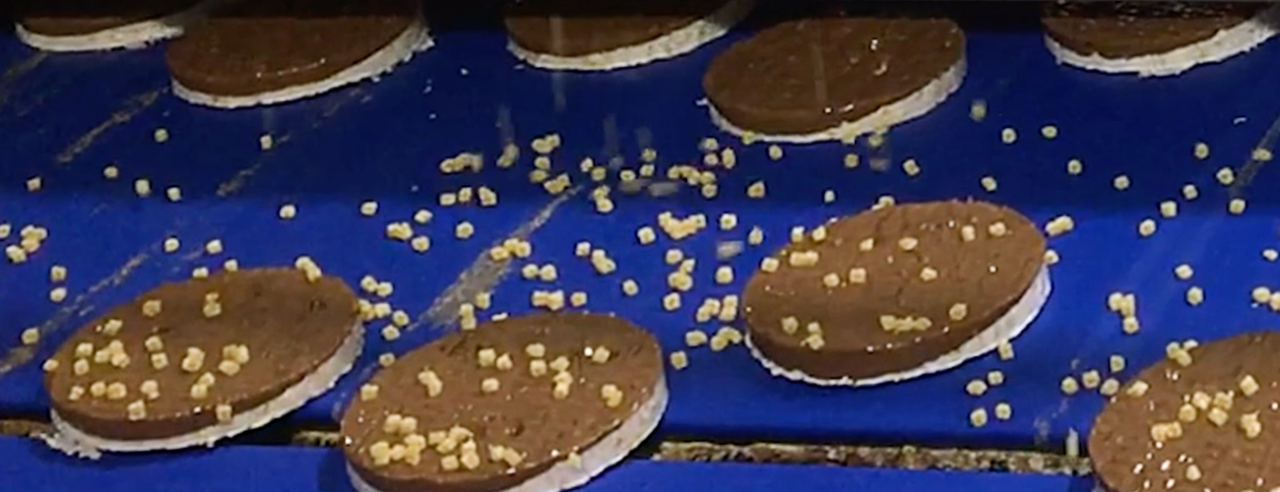

With a granulate decorating machine, you can effortlessly apply toppings such as chopped hazelnuts, crispy sugar pearls, pieces of dried fruit, and other crunchy or decorative ingredients. These decorations not only add appealing texture but also enhance the flavour experience and visual impact of your chocolate product.

Betec’s granulate sprinklers are designed for even and reproducible distribution, regardless of the type of topping. Thanks to the adjustable spreading quantity and precise layout, you maintain full control over the final result.

To minimise material loss, the installation can be equipped with a recycling system. As the name implies, unused granulate is collected and re-fed into the machine. This system ranges from a simple collection tray to a fully automated return conveyor leading to the buffer hopper. A rotating sieve removes clumps or impurities, so the recovered granulate can be reused without clogging.

Depending on your production line, these sprinklers can function as a stand-alone unit or be integrated into an existing line. They are available in various working widths and can be fully customised.

Advantages:

- Suitable for different types of granulate (dry or slightly sticky)

- Easy-to-adjust settings for a uniform result

- Hygienic design with quick cleaning

- Optional: vibration or brush system for non-overlapping decoration

- Expandable with advanced recycling system

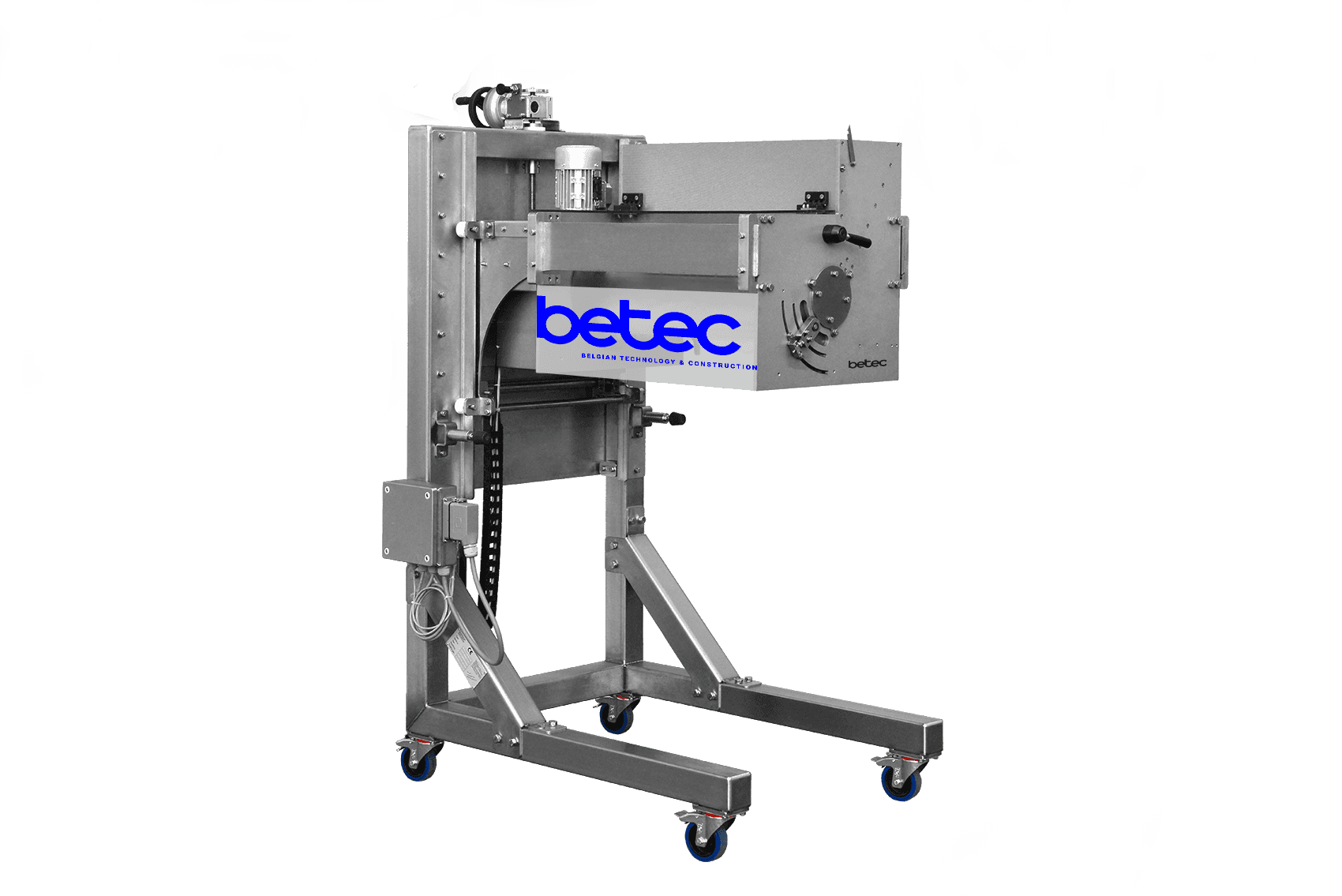

1. Granulate Drum Decorator – Automatic Sprinkling Machine

Would you like to finish your products with crunchy decorations such as nuts, sugar pearls or crispy toppings? Then the Granulate Drum Decorator is your ideal solution.

This automatic sprinkling machine distributes the granulate evenly across the surface of your pralines, bars, or pastries, ensuring an attractive and uniform presentation. The system is easy to adjust, suitable for various types of toppings, and integrates smoothly into your existing production line.

2. Sprinkler “Rainfall” Decorating Machine – For Delicate Sprinkle Decorations

Light or sticky decorations, such as coconut flakes, require gentle and controlled application. The Sprinkler ‘Rainfall’ decorating machine evenly distributes these fine, sticky ingredients over your products – as if they’re gently falling like snowflakes. This system ensures an elegant and consistent finish, without clumping or ingredients sticking to the machine. Ideal for artisanal presentations where visual finesse is key.

The sprinkler can be used stand-alone or integrated into an existing production line. Settings for drop height, spread, and product spacing are easily adjustable.

Benefits:

- Gentle handling of delicate or sticky decorations

- Even distribution without clogging

- Hygienic design with easy cleaning

- Perfect for coconut

3. Multi Granulate Decorating Machine – flexible decorating with one system

.png)

Would you like to apply both traditional granulates (such as nut pieces or sugar pearls) and light, fine decorations (such as coconut flakes)? Then the Multi-Granulate Decorating Machine is the ideal solution. This versatile system combines the operation of the Granulate Drum Decorator and the Sprinkler 'Rainfall' in one compact unit. This allows you to apply various types of decoration harmoniously and precisely to your chocolate products – without having to switch machines or installations.

The machine is suitable for placement on a conveyor belt and is fully adjustable per product type, with flexible parameters for sprinkling pattern, drop height and distribution.

Advantages:

- Suitable for both heavier granulates and fine, sticky toppings

- Two decorating principles in one integrated system

- Quick switch between decoration types

- Compact, hygienic design with easy cleaning

- Ideal for flexible production lines with changing assortments

Precision Decorating Machine for Granulate Toppings – For Clean Finishes with Visual Impact

Do you prefer to apply just a few granules of decoration on a specific spot of your praline? Then the Precision Granulate Decorating Machine from Betec is the ideal solution. This machine is designed for ultra-precise dosing. It can place even a single salt crystal or sugar particle exactly where you want it – consistently, piece by piece.

The result? A clean, elegant design that not only looks refined, but also adds a surprising flavour accent. Perfect for caramel-filled pralines, salted notes or luxury signature decorations.

Benefits:

- Grain-level precision dosing

- Ideal for designer pralines or products with a subtle accent

- Full control over placement and quantity

- Compact and hygienically built

- Suitable for small and medium-sized production lines

Decorating with chocolate, compound and sugar mass: Create artistic lines

Chocolate Decoration: Cost-Effective and Versatile

Chocolate is not only delicious but also one of the most cost-effective ways to decorate your products. Compared to other decorating materials, chocolate is often more affordable – while offering endless possibilities. From clean lines to playful patterns, with lots or just a touch of chocolate, in one or multiple colours: you decide the style.

Whether you opt for a uniform pattern or a handcrafted effect with subtle variations – with the right chocolate decorating machine, you can make the most of every detail.

Our standard chocolate decoration machines (also called striping machines or drislers) are designed to apply fine lines or bands in various patterns along your product. They are suitable for chocolate, compound, or other sugar masses, and offer both precision and versatility.

Discover the advantages:

- Heated and enclosed environment: Every Betec striping machine is equipped with a heated chamber, enclosed in plexiglass, to keep the chocolate at the ideal temperature and ensure uninterrupted decorating.

- Automatic cleaning system: Thanks to the built-in rinsing system, clogged nozzles or leftover residue are no longer a concern – improving reliability and reducing maintenance.

- Versatile applications: Whether you're looking for a stand-alone machine or an integrated decorating unit for your enrobing line (like our E-series), we tailor the machine to fit your production process.

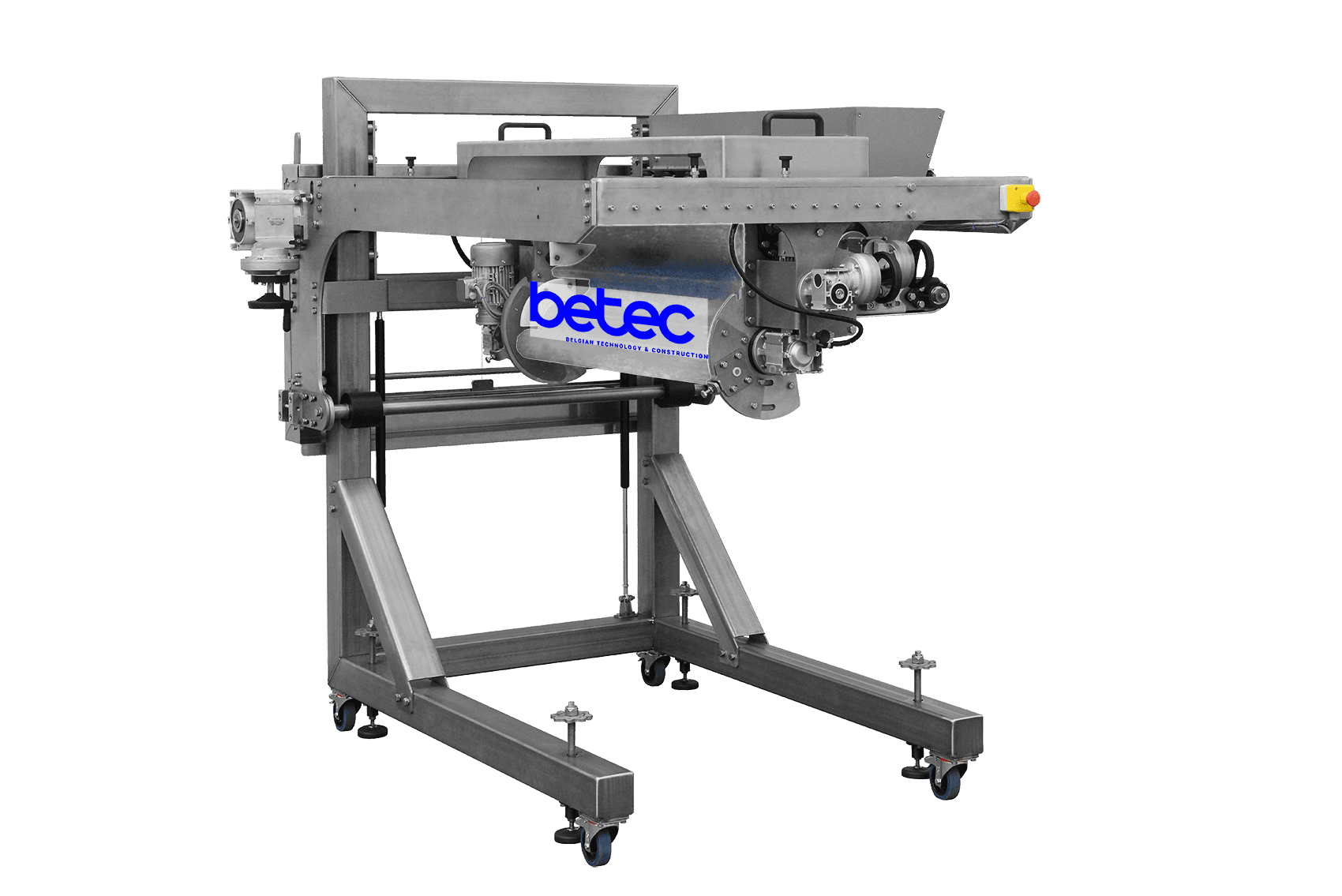

LD1-500 striping decorator – for neat lines across the product

The LD1-500 is the ideal choice for applying chocolate lines across pralines, cookies or bars. This automatic decorating machine is typically placed above an enrobing machine, at the infeed of a moulding line, or just before the cooling tunnel. It creates a consistent and artisanal pattern that immediately catches the eye.

With its heated pump, adjustable spray height and mobile frame, the LD1-500 integrates seamlessly into nearly any production line. You choose the decoration pattern: straight, diagonal or alternating lines – always with a uniform, elegant finish.

The machine is designed for easy cleaning and simple operation, making it ideal for producers aiming to combine speed and precision.

Benefits:

- Suitable for chocolate, compound or sugar mass

- For decoration across the product

- Adjustable for straight, diagonal or playful patterns

- Mobile and height-adjustable

- Works above enrobing line, moulding line or cooling line

Cocoa powder machine for coating truffles with a delicious layer of cocoa powder

.png)

Truffles – irresistible and delicious, especially with that delicate layer of cocoa powder around each piece. But achieving a uniform coating isn't easy: it's labour-intensive and often creates fine dust in the workspace.

On a small scale, this is usually done manually, in a powder tray or a simple rotating table. A round table offers the benefit of allowing freshly coated truffles to fall separately into the powder, preventing them from sticking or getting damaged. Manual coating carries a greater risk of deformation or incomplete coverage.

For larger productions, Betec offers an efficient solution: the CPM 800, an advanced cocoa powder machine. This machine automates the entire process, limits waste and keeps the working environment dust-free. Excess powder is neatly collected in an integrated reservoir and is fully reusable.

And the best part? Once filled, the CPM 800 operates fully unattended – so you no longer have to stand in the dust and can focus on the rest of your production.

Advantages of the CPM 800 cocoa powder machine:

- Uniform coating – for a consistent, professional finish on truffles and coated items

- Efficient production – less manual labour, higher output

- User-friendly interface – intuitive colour touchscreen

- Durable construction – fully made of AISI 304 stainless steel and equipped with standard components

- Powder recycling – minimal waste, maximum profitability

Give your products character with Betec’s decoration expertise.

Every decoration tells a story. With the right decorating machine, you not only enhance the appearance, but also the recognisability and experience of your chocolate creations. At Betec, we’re happy to help you find a solution that fits your production process and desired finish.

Curious about the possibilities or looking for a custom model? Browse our online catalogue or contact us for advice or a tailored quotation. Use the links on the side to explore the machines that best match your decoration needs.

Frequently Asked Questions about Chocolate Decoration (FAQ)

1. How can I prevent granulate from falling off during transport or packaging?

Proper adhesion starts with the right timing of decoration: apply the granulate right after enrobing, while the chocolate coating is still soft and not yet crystallised. This helps the decoration stick better. The size of the granulate and the applied quantity are also crucial.

2. What is the difference between a spreader and a sprinkler?

A spreader is designed for larger and heavier decorations like nuts, crunch or pieces of dried fruit. These are distributed using vibration or conveyor systems. A sprinkler (also known as a "rainfall" system) is ideal for fine, light or slightly sticky decorations like coconut flakes. These are softly tossed up and fall like snowflakes — resulting in a light, artisan-style finish without clumping.

3. Can I use different types of granulate with one machine, or do I need separate units?

That depends on the type of decoration and the desired precision. For decorations with similar properties, one machine with adjustable settings will usually suffice. For greater variety or precise placement, a multi-granulate decorating machine is ideal. It combines multiple techniques and enables fast switching.

4. Most decorating machines make lines along the product length, but I want to decorate across the width. Is that possible?

Yes, absolutely. The LD1-500 line decorating machine is specifically designed to apply chocolate lines across the product — ideal for bars, cookies or pralines with a distinctive visual accent.

5. I want to decorate but would prefer not to buy extra ingredients. What is a budget-friendly solution?

If you're already working with chocolate, you can easily use liquid chocolate as decoration — for example, as lines. This avoids extra purchases and storage of other ingredients. With white chocolate and a bit of colouring, you can even create vibrant decorative accents: simple, effective, and budget-friendly.

6. Can your decorating machines be integrated into an existing production line?

Definitely. Our decorating modules are modular and can function either stand-alone or be positioned above or behind existing machines such as enrobing lines, cooling tunnels, or moulding lines.

7. Are there solutions for powder decoration, like cocoa or sugar?

Yes, including our CPM 800 cocoa powder machine. It evenly distributes powder decorations over truffles or other products and works fully automatically with minimal powder loss.

8. How can I avoid over-decoration or excessive sprinkling?

Our granulate decorating machines come with adjustable parameters for both the amount and distribution of the granulate. This allows you to fine-tune the decoration for each product type. These settings ensure even distribution and prevent build-up or excess.

Whatever finish you’re aiming for — we’re happy to help you find the best fit.

Whether you want to create fine chocolate lines, sprinkle crunchy toppings, or apply a powder coating, Betec offers a customised solution for your production.

.png&w=1920&q=60)

%20-%20DSC_5304%20B_.png&w=1920&q=60)

.png&w=1920&q=60)