Betec depositing machines: Accurate and efficient depositing for excellent results

Before the advent of modern depositing machines, chocolate and other fillings were mainly dosed manually using piping bags, funnels with basic shut-off systems, or even spoons. These methods required a lot of skill and experience to achieve consistent results. Moreover, they were often time-consuming and less hygienic.

From artisanal methods to advanced depositing technology

Although these methods are still used today by smaller artisanal chocolatiers or in test labs, manual depositing no longer meets the demands of an efficient production environment.

That’s why Betec offers a wide range of depositing machines – also known as chocolate dispensers – specifically developed to quickly, accurately, and hygienically dose a variety of liquid masses, such as chocolate and different types of fillings, with or without inclusions. These advanced systems ensure an efficient and consistent depositing process, improve product quality, and optimise production capacity. Precision in depositing reduces product loss and improves the final product.

Volumetric depositing machines, type FM and FMD: for advanced filling operations

.png)

The volumetric depositing machine type FM (Filling Machine) is designed for the precise depositing of liquid or semi-solid fillings such as ganache, caramel, or cream into polycarbonate moulds. The machine features its own chain conveyor and can optionally be equipped with an automatic mould destacker. After depositing, the moulds are vibrated to remove air bubbles and ensure even distribution of the filling.

For applications involving multiple fillings, there is the FMD version: an FM machine with two integrated depositing stations operating in tandem. This allows you to deposit two different fillings directly in sequence into the same mould – for example, a layer of caramel followed by an airy mousse – ideal for layered pralines or complex recipes.

Both FM and FMD machines can deposit fillings containing small inclusions, such as nut pieces, raisins, or crisp pearls, with a maximum particle size of 3 mm.

Each depositing head can be fitted with a double hopper, enabling the second filling to be prepared while the first is still being deposited. This increases flexibility and output capacity, especially when using multiple fillings in combination.

CFD Volumetric C-Frame Depositor: Specialist in Depositing Various Fillings

.png)

The CFD volumetric depositing machine, also known as the Betec C-frame depositor, is ideal for those who want to deposit or dose fillings with precision and flexibility. This machine is used by both artisan chocolatiers and mid-sized chocolate producers. For higher production levels, an industrial version is available without hoppers, in which the filling is continuously supplied via a flow-through system. As a result, the operator no longer needs to monitor the buffer hopper level and can focus on other steps in the production process.

The CFD machines are built in a compact C-frame and come standard with piston-driven volumetric dosing. This version is suitable for fillings containing inclusions up to the size of a whole hazelnut. As an alternative, the machine can be equipped with a gear pump, enabling continuous dosing without pauses – without inclusions – ideal for applications requiring high-speed dosing and uninterrupted flow. Depending on your production setup, the CFD can be supplied with its own conveyor belt, or integrated over an existing conveyor or cooling tunnel.

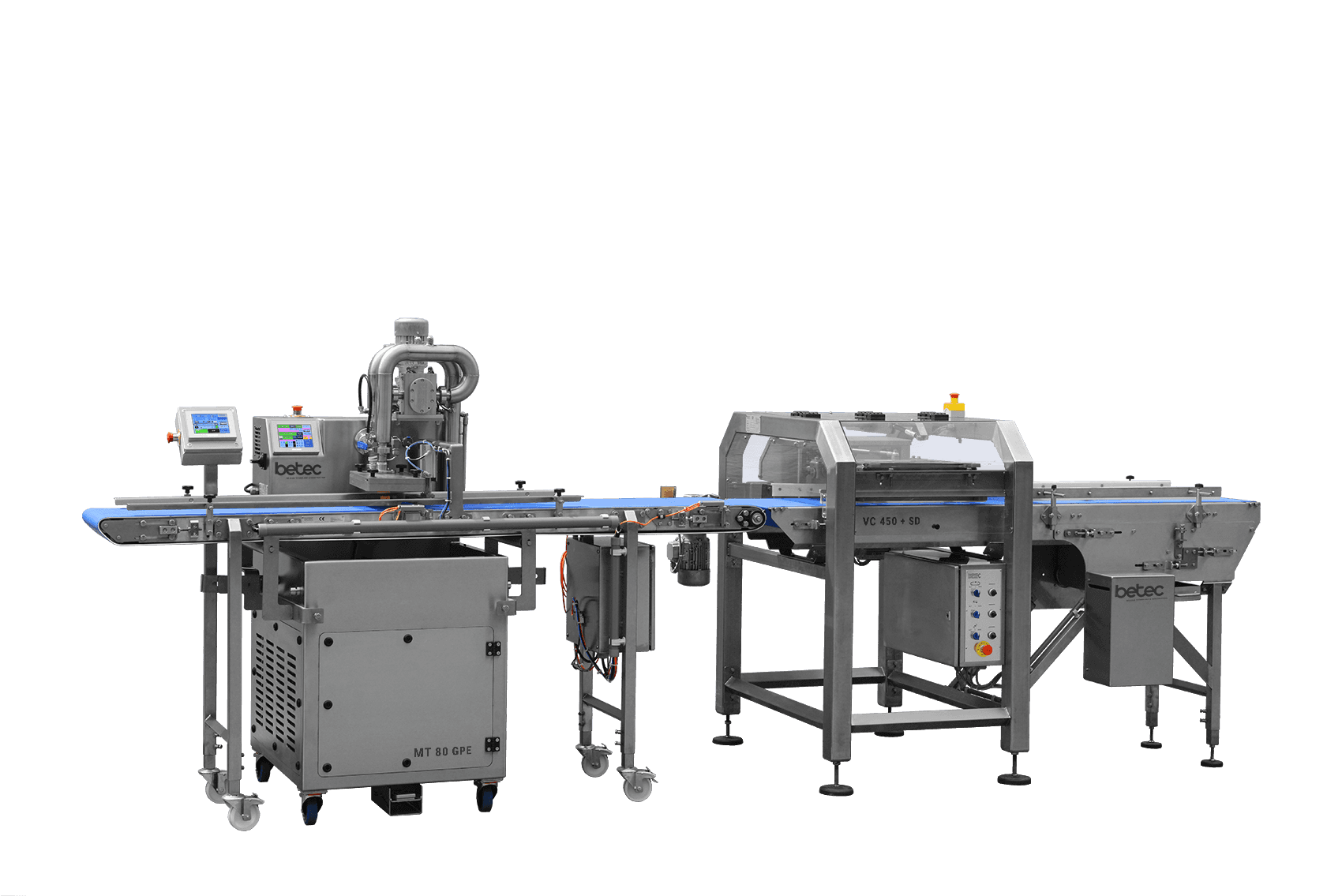

Automatic tempering machines with separate dosing pump

Betec’s automatic tempering machines, such as the MT 80 GPE and MT 80 GPI, are compact systems designed for the precise dosing of tempered chocolate. Both models feature a separate dosing pump, but differ in setup:

- The GPE version has the dosing pump mounted on top of the tempering machine.

- The GPI version has the dosing pump integrated into the machine’s frame.

These automatic tempering-dosing machines are especially suited for filling polycarbonate moulds, blisters, and other types of moulds. Thanks to accurate pump settings, each cavity or mould recess is filled with exactly the same amount of chocolate – ensuring a uniform and consistent end result, essential for those aiming for repeatable quality.

For those working with hollow moulds that contain different types of figures, these machines offer a valuable extra: the program includes quick selection menus that allow you to switch between four preset pump timings. This enables you to easily alternate between different cavity sizes within one mould, without needing to manually adjust the settings each time.

For hollow figure applications, Betec also developed a special dosing head with individual stainless steel pipes, which can be quickly and easily adjusted into position. This is especially useful for moulds with mixed figures – such as bunnies, chicks, and eggs in a single tray – which are hard to dose efficiently using a classic nozzle.

In addition to the MT 80 series, Betec also offers the AT 120 GPI – a more powerful version featuring even more stable tempering and a high-precision dosing system, ideal for larger volumes or intensive use.

One-shot depositing machines: chocolate and filling in a single step

.png)

For those who want to produce chocolate products in a single operation – with both chocolate and filling – Betec offers two powerful solutions: the Boss 275 and the Boss 2x 32P 3D. These one-shot dosing machines are designed to create filled chocolate products such as pralines, bonbons, or tablets with a soft center filling.

Boss 275 – Efficient and versatile one-shot system

The Boss 275, also known as the Betec One Shot System, is equipped with two buffer hoppers (one for chocolate and one for filling) and a set of interchangeable dosing plates. Using gear pumps, the machine doses both the chocolate shell and the filling in one motion, without pre-suction. This enables continuous dosing and significantly boosts production speed. The Boss 275 can also be used as a standard filling machine, offering extra flexibility – from single fillings to one-shot applications. The machine can be supplied with its own transport conveyor, or mounted above an existing conveyor, cooling tunnel, or moulding line.

Boss 2x 32P 3D – Maximum versatility in one machine

The Boss 2x 32P 3D is the most versatile one-shot machine in the Betec range. It is equipped with piston pump technology and offers a wide range of advanced features:

- Standard dosing and classic one-shot production

- 3D one-shot dosing thanks to movement in X, Y, and Z directions

- Combination of two fillings in one product (e.g. caramel and mousse)

- Filling of tablets or figures with larger inclusions, such as whole hazelnuts (optional slide valve)

Thanks to these unique capabilities, the Boss 2x 32P 3D is suitable for a wide variety of applications – from standard pralines to complex, seasonal products like Easter eggs, Christmas figures, or Valentine hearts. One machine, many possibilities – always in one smooth operation. This model too can be equipped with its own transport conveyor, or easily integrated above an existing line, cooling tunnel, or moulding system.

Each application requires a well-considered approach.

Tell us what you want to achieve, and we’ll work together to find the right dosing technique. Feel free to contact us or browse our online catalogue to discover the possibilities.

Frequently Asked Questions about Chocolate Dosing (FAQ)

1. What is the difference between a filling machine and a one-shot machine?

A filling machine only doses the filling into a mould or product. A one-shot machine doses both chocolate and filling simultaneously in a single action.

2. Can I work with different types of fillings using the same machine?

Yes, most Betec dosing machines can handle multiple recipes or filling types. In many cases, flushing the machine is enough before continuing with production – just select the right settings or hopper.

3. Can I use two different fillings during a single production run?

Yes, both the FMD (double filling machine) and the Boss 2x 32P 3D (one-shot with double filling) can dose two fillings either sequentially or simultaneously in the same cycle – ideal for layered or combined pralines.

4. Are the dosing machines suitable for fillings with inclusions (bits or pieces)?

Absolutely. Depending on the machine and technique, inclusions up to 3?mm (FM/FMD) or even whole hazelnuts (Boss 2x 32P 3D) can be processed.

5. Can I integrate the machines into my existing production line?

Yes, all Betec dosing machines can be supplied with a custom conveyor or installed above existing production lines, transport belts, or cooling tunnels.

6. What is the advantage of a machine with a double hopper?

With a double hopper, the next filling can be prepared while the first is still running. This significantly improves efficiency.

7. How accurate are the dosing machines?

The machines dose with high precision thanks to servo-driven motors, ensuring consistent product quality.

8. Are there dosing machines for tempered chocolate?

Yes, Betec offers compact models like the MT 80 GPE and GPI, suitable for small to medium batches. For larger volumes, the AT 120 GPI is a better choice.

9. Can I quickly switch between different dosing times or mould types?

Yes, the GPE and GPI models in the MT and AT series include program menus and quick selection buttons. Combined with a custom holle mould dosing head, you can easily adjust center distances between figures.

10. What if I have a specific application not mentioned here?

Don’t hesitate to contact us. We’ll be happy to help you find a customized solution.

11. Who invented the concept of filled pralines, and where?

The first true filled praline was created in 1912 by Jean Neuhaus Jr. in Brussels. His grandfather, a pharmacist, used chocolate to mask the taste of bitter medicines. Jean Jr. had the idea to fill a hollow chocolate shell with a soft cream filling – a concept that did not exist before. His invention laid the foundation for what would become industrial filled chocolate dosing: shell and filling in a single process. His creation was the starting point for the modern praline we know today.

Looking for control, precision and flexibility in your dosing process?

Whether you’re dosing a single type of filling or producing seasonal products with multiple layers – individually or all in one shot – the right dosing machine makes all the difference. We’re happy to support you with tailored advice and customised solutions.

.png&w=1920&q=60)

%20-MODEL%20%202%20B.png&w=1920&q=60)