What is enrobing?

Enrobing is the process of coating products with a thin layer of chocolate, glaze, or another finishing substance. Think of biscuits, pralines, candy, nuts, cake, or even frozen treats like ice cream or ice cream cakes. This final touch not only adds flavour and visual appeal, but also extends the shelf life of the product.

From manual dipping to automated perfection

Before the arrival of enrobing machines, this process was done entirely by hand. Products were individually dipped into a liquid coating – such as tempered chocolate, warm compound, fruit coulis, or sugar-based mixtures – often using a fork or dipping tool. For larger quantities, multiple items were dipped simultaneously on a tray, then carefully placed on a wire rack to harden.

This manual work was time-consuming, labour-intensive, and prone to error. It was difficult to apply a uniform coating each time, and it took skill to finish every product visually identical without damage. The time between coating and cooling was also inconsistent, which affected both the quality and speed of the process.

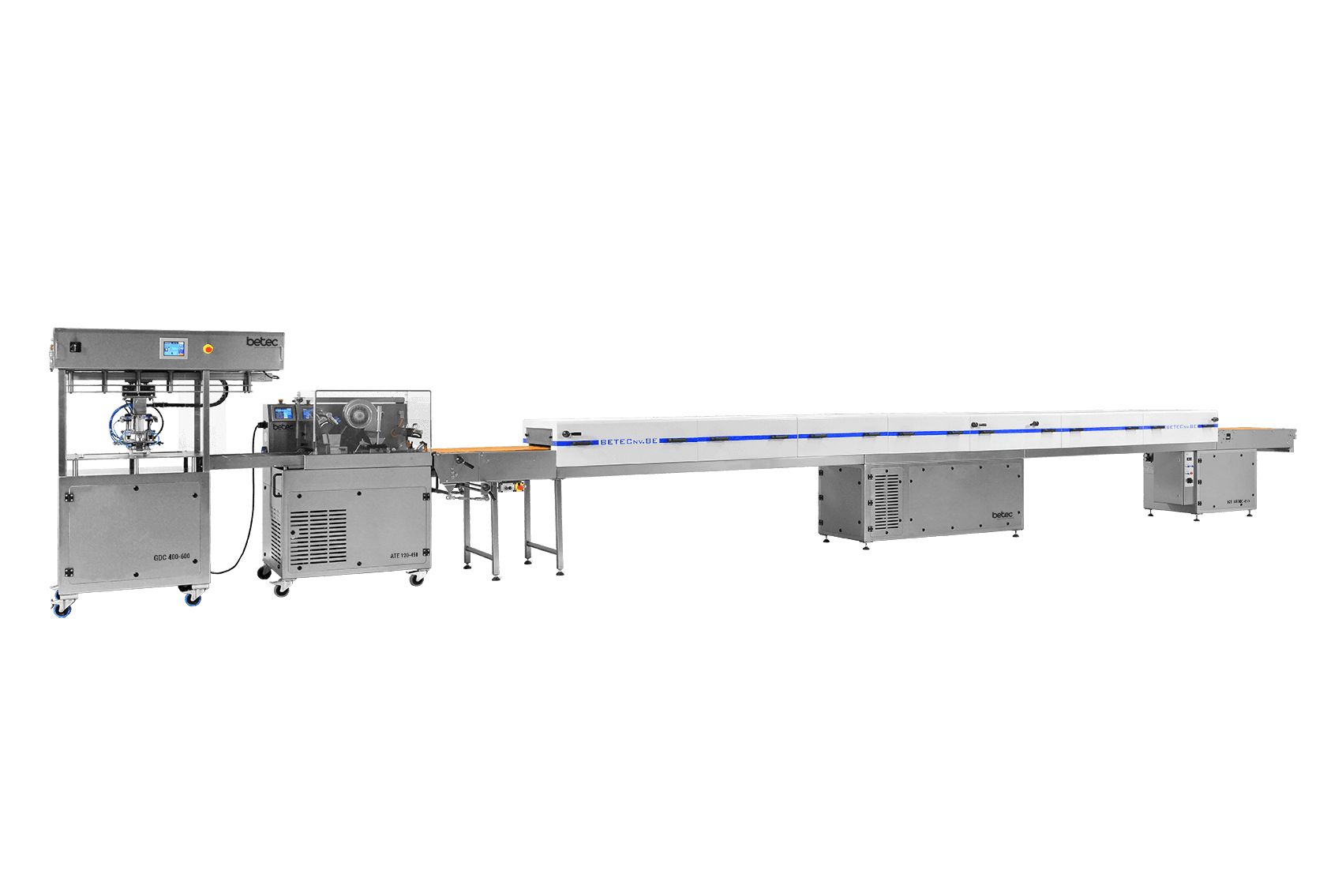

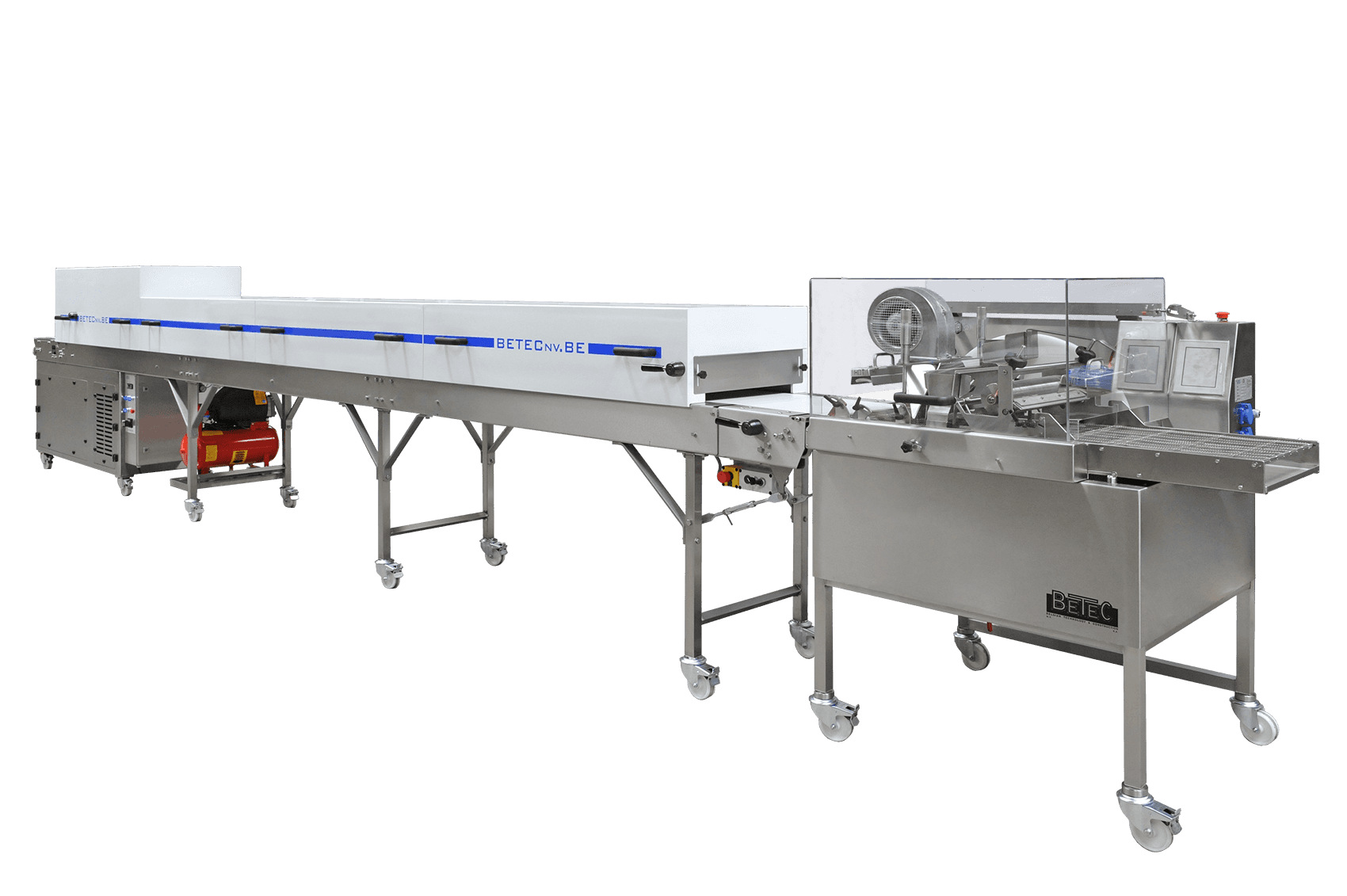

Today, automated enrobing technology represents a major leap forward. The coating is applied via a chocolate curtain and bottom pool, after which air blowers and vibration systems can be used to fine-tune the thickness of the chocolate layer. The products then move automatically across a wire conveyor towards the outfeed or cooling tunnel. This minimises manual handling and delivers a faster, more consistent, and hygienic result – perfectly aligned with modern production demands.

Not every product requires a full chocolate coating. With specialised machines like the bottommer, you can selectively apply a uniform layer of chocolate to the underside of your products – ideal for clusters or delicate snacks. The smart design allows easy access to the bottom tray from both sides, making it perfect for manual dipping when crafting clusters.

The art of enrobing lies in the careful application of a visually appealing and flavourful outer layer.

Our commitment to top quality and innovation

At Betec, we always start from your real-world needs. Our first enrobing machines were developed for semi-industrial applications, with a focus on ease of use, reliability, and easy maintenance. What sets us apart? While others tend to “scale up” their small machines later, we started from the larger models. Our compact enrobing and covering machines are designed with the same qualities as their bigger counterparts – robust, dependable, and fully tailored for professional use.

The result? You get a smaller machine with all the advantages of a full-scale industrial unit – perfectly suited to your production environment and specific needs.

Smart Features of the Betec Enrobing Conveyor

Designed to Enhance Your Enrobing Process

Every Betec enrobing conveyor is built with one purpose: to make your work easier and more effective. From adjustable features to smart details that save you time and effort – these machines are designed to grow along with your craft or production.

Curious what makes them so unique? Discover the practical differences below:

- Independently switchable feed belt

A convenient lever lets you start and stop the infeed grill independently from the enrobing section. Ideal for solo operators: calmly load the belt, then run everything through in one go. This saves both time and materials like transfer sheets or decorative elements. - Adjustable chocolate curtain

Height and thickness can be adjusted for perfect product coverage – tailored to every shape and size. - Height-adjustable bottom bath

Fine-tune the bottom layer for flawless underside coating – ideal for a uniform chocolate base. - Variable-speed air blower

Set the airflow strength, height and angle to remove excess chocolate. You can even create a wave effect on top of your product. - Vibration function

Adjustable vibration intensity for optimal chocolate distribution. Essential for an even finish without build-up. - Compensation lick roller

Switchable on or off depending on your product. Ensures the perfect “foot” under your product – thick or thin, always cleanly sealed underneath. - Heated and adjustable tail cutter

Rotation direction, height and temperature can all be adjusted. Neatly finishes the product without unwanted chocolate “tails” on the outfeed belt or in the cooling tunnel. - Overpour grill, glazing belt or enrobing band under plexiglass cover

The heated workspace with one or more adjustable infrared heaters keeps chocolate fluid and prevents it from solidifying on the grill. This prevents build-up and simplifies starting up a new production run.

For small to medium-scale applications: Seamless integration with tempering machines

Our compact enrobing conveyors, with belt widths from 240 to 450 mm, integrate seamlessly with various Betec tempering machines. These include the MBE series (wheel machines), MTE series (mini tempering machines), ATE series (for higher volumes), E series (without temperature unit), and the B series (bottommers for bottom-only coating).

What makes these setups especially convenient?

The overpour, glazing, or enrobing belt can be quickly and easily removed. This allows you to switch chocolate types or product formats effortlessly, without having to modify the entire machine – ideal for manual use and smaller batches. For automatic tempering machines, internal cleaning is understandably more complex, typically done through flushing. Even so, the modular design ensures you can switch setups quickly for a new production run.

After enrobing, products cannot be handled manually right away – they must harden first before further processing.

There are several solutions for this:

- Outfeed conveyors (for 240 to 450 mm belts) neatly collect the products on crystal paper. This paper can be trimmed and placed on trays, ready for the cooling room.

- For a fully automated process, a cooling tunnel can be added behind the enrobing line. Products are immediately cooled and set after coating – perfect for a smooth production flow and consistent results. Be sure to check our Cooling Applications page for more details on available tunnels.

For industrial applications: maximum capacity and easy maintenance

For large-scale production, Betec offers enrobing conveyors with belt widths from 600 to 1600 mm. For these industrial applications, we developed the E-series enrobing machines – robust systems designed for continuous operation.

Each industrial enrobing, overpour, or coating machine in this range comes standard with a sliding conveyor belt and removable chocolate container. Thanks to the dedicated trolley system, designed for smooth removal and reinsertion, cleaning and maintenance are faster and more efficient. This way, your production keeps running with minimal downtime.

Tailored to Your Specific Needs

Betec also develops customised solutions for coating a wide range of products in the bakery and confectionery sectors. Think of cookies, donuts, cakes, dried fruits (like bananas and apples), as well as frozen treats like ice cream cakes, frozen pralines or truffles.

Our machines are tailored to your products and requirements, ensuring a perfect coating every time – whether it’s with chocolate, glaze, or other sugar- or fat-based masses.

Your product, our passion for perfection.

Discover how we can create your ideal coating solution together. Betec is ready with solutions that grow alongside your production process – from artisanal to industrial scale.

Contact us directly or browse through our online catalogue to explore what we can do for you.

Frequently Asked Questions about Chocolate Coating and Enrobing (FAQ)

1. What is the difference between enrobing and dipping?

Dipping involves manually immersing each product into a liquid coating like chocolate, usually with a fork or tong, or several at once on a rack. This traditional method is time-consuming and requires skill, especially for larger volumes.

Enrobing is automatic: products pass under a chocolate curtain and sometimes through a bottom bed, ensuring a fast and even coating. The result is consistent quality with less manual labour.

2. Can I add decoration during enrobing?

Yes. Decorations like sprinkles, nuts, or chocolate strings are typically added right after enrobing but before cooling. You can use integrated decoration units like sprinklers, granulate decorators, or chocolate stringers. These systems align easily with your line and enhance your product's visual appeal.

3. Which settings influence the coating thickness?

The key factors are:

- Chocolate temperature: lower (but still liquid) temperature results in a thicker layer.

- Curtain thickness: the thicker the curtain, the more chocolate adheres to the product.

- Blower strength: adjustable fans remove excess chocolate.

- Vibration intensity: more vibration leads to better drainage.

- Conveyor speed: slower movement usually results in a thicker coating.

By fine-tuning these settings, you control the exact thickness of the chocolate layer.

4. Can I use sugar glazes or other coatings in an enrobing machine?

Yes, but this requires a custom setup. Sticky coatings like icing require a glazing belt with polycord transport and cleaning scrapers to avoid buildup or machine downtime. Our glaze systems are specially designed for this purpose.

5. What are the advantages of a removable enrobing belt?

A removable enrobing belt provides maximum flexibility and ease of use. Especially useful for smaller productions or when switching chocolate types regularly.

Benefits include:

- Faster changeover: remove the belt in seconds to fully access the chocolate tank – ideal for product switches.

- Easier cleaning: better access to machine parts.

- Time-saving for flavour or colour changes: no full machine clean required.

- Efficient flushing with automatic tempering units: the belt can be removed for unimpeded rinsing. In short, a removable belt makes your production cleaner, more efficient and more flexible – without compromising functionality.

6. Why is chocolate considered a luxury product?

Chocolate has always been something special. The Maya and Aztecs even used cocoa as currency. Today, chocolate remains valuable due to its taste and the craftsmanship and care involved in its preparation – such as in enrobing.

7. Does product shape influence flavour perception?

Yes! Studies show that round shapes are often perceived as sweeter than angular ones. So the shape in which you cast or enrobe your chocolate can influence the taste experience – an interesting insight when designing your products.

8. Why does chocolate make people feel happy?

Chocolate contains compounds that trigger the release of endorphins – the “happy hormones”. Combined with a smooth texture and perfect coating, chocolate offers not just taste, but a feel-good moment for your customer.

With the perfect coating from your Betec machine, you elevate that moment of chocolate bliss even further.

.png&w=1920&q=60)

%20-%20DSC_8946%20C%20.png&w=1920&q=60)

%20-%20DSC_7772%20B_.png&w=1920&q=60)

%20-%20DSC_6803%20I.png&w=1920&q=60)

%20-%20DSC_5658%20G%20.png&w=1920&q=60)

%20-%20DSC_6803%20B(3).png&w=1920&q=60)