Product

DH-series

Dosing Heads for Chocolate and Filling Applications

BETEC designs and manufactures various types of dosing heads, each developed for a specific chocolate application — from tempered chocolate to fillings and one-shot production. Whatever mass you are processing, we build a dosing head that perfectly matches your machine, mould type, and product.

Our solutions are used on tempering machines, filling dosing machines, and one-shot installations, and are available in both standard and fully custom-made versions.

Overview of Our Dosing Heads

1. Dosing Heads for Tempered Chocolate

For mounting on our tempering machines. Suitable for solid products, hollow figures, and the precise filling of polycarbonate moulds or blisters. On this page, you will discover, among other things:

- CMDH – fully custom-made dosing heads with base plates (for solid products and fixed mould patterns)

- EAD – adjustable dosing heads with flexible outlets (for hollow figures and variable positions)

2. Dosing Heads for Fillings and Cream Products

For our piston dosing machines. These heads dose ganache, caramel, praline, and other semi-liquid fillings accurately and quickly. Each head is designed to match your blister and mould patterns.

3. Dosing Heads for One-Shot Systems

For the simultaneous dosing of chocolate and filling. We develop custom-made dosing heads for Betec machines as well as systems from other manufacturers. Including solutions for double fillings, large inclusions, and shut-off valves.

Discover below which dosing head best fits your production.

Each application requires a specific configuration — and we explain these in further detail below.

1. Dosing Heads for Tempered Chocolate

These dosing heads are suitable for Betec tempering machines and—if desired—for machines from other brands. They are used for:

- solid chocolate products

- hollow figures

- precise filling of polycarbonate moulds

Within this category, we distinguish two models: CMDH and EAD.

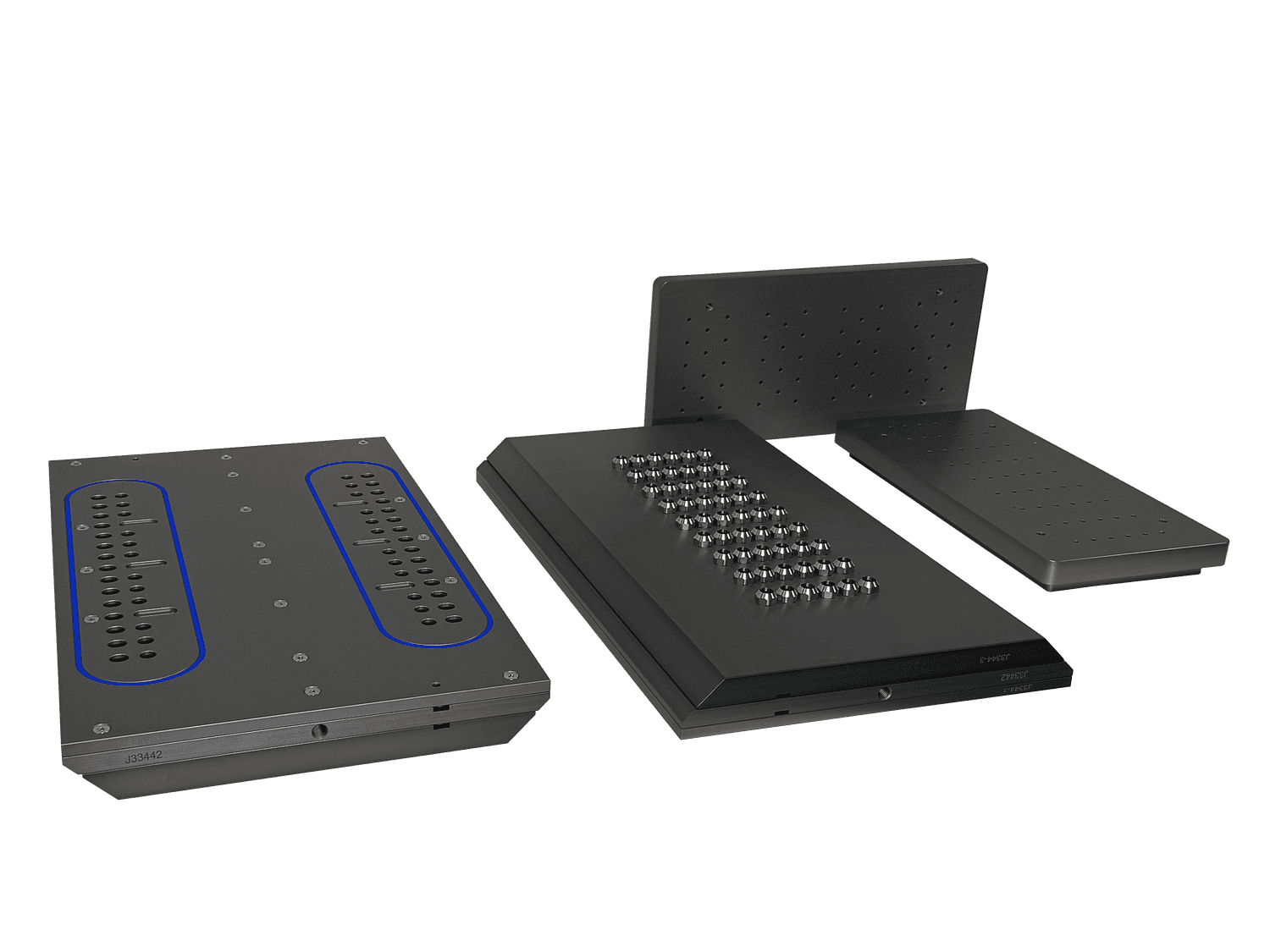

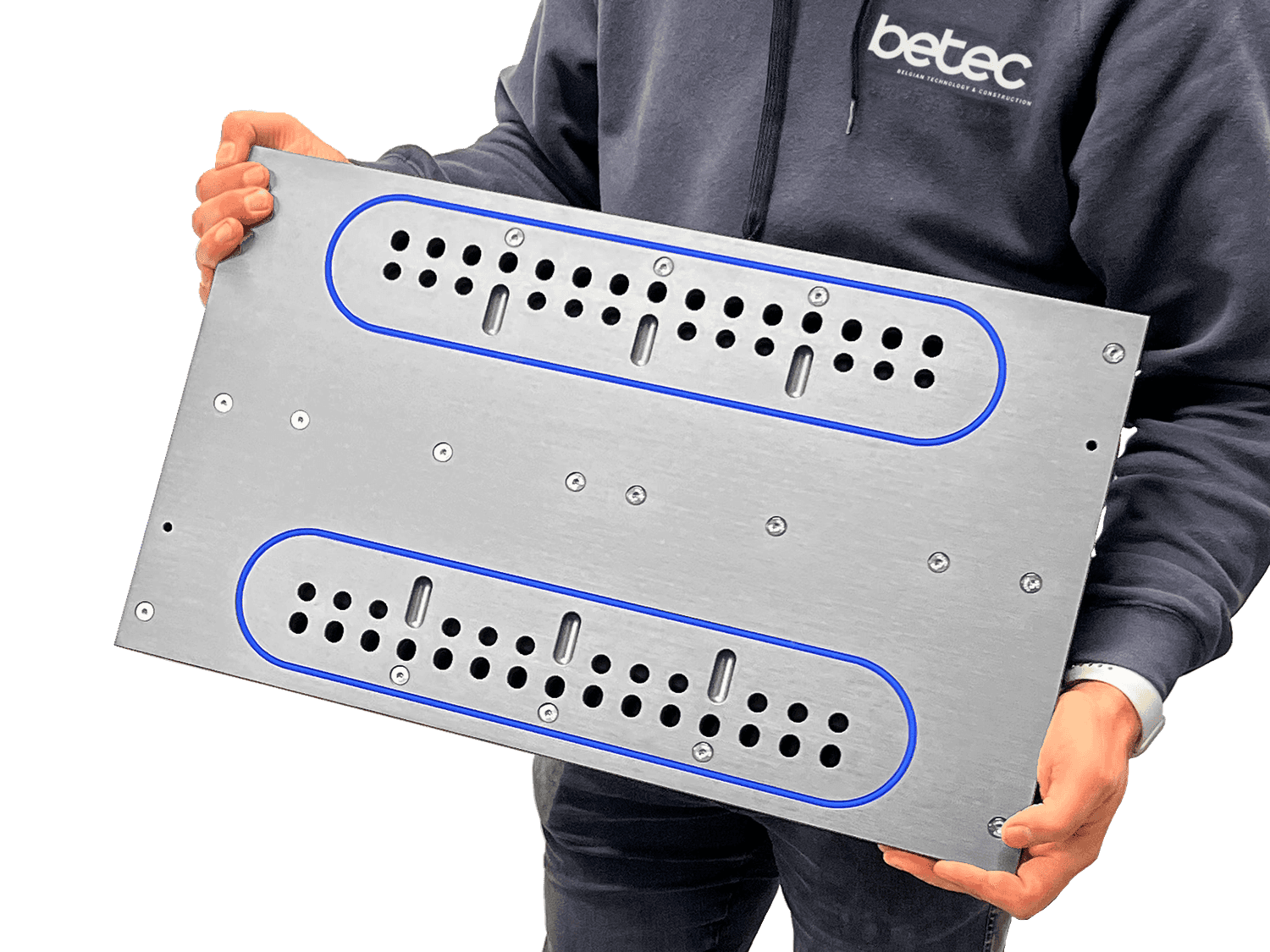

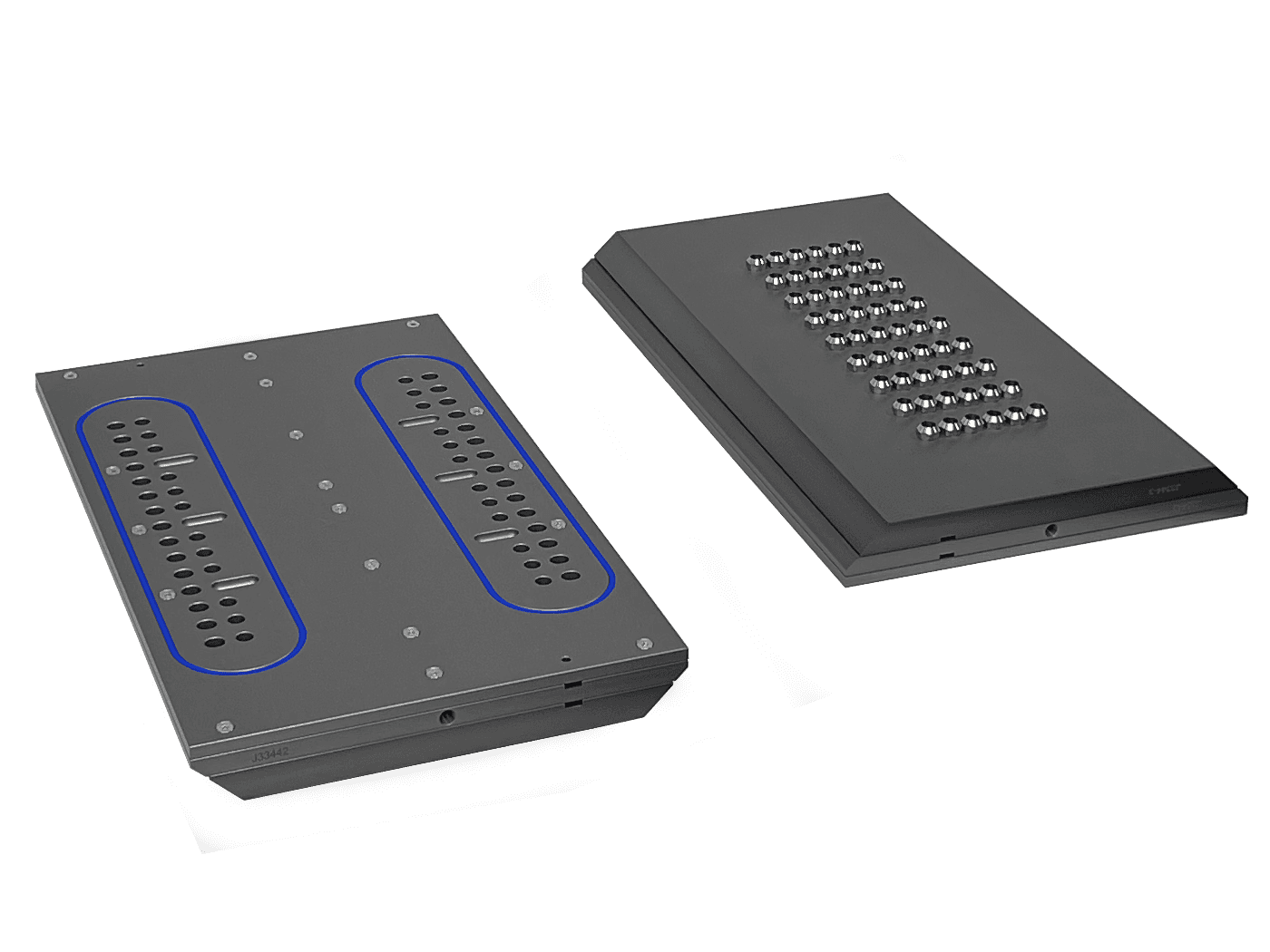

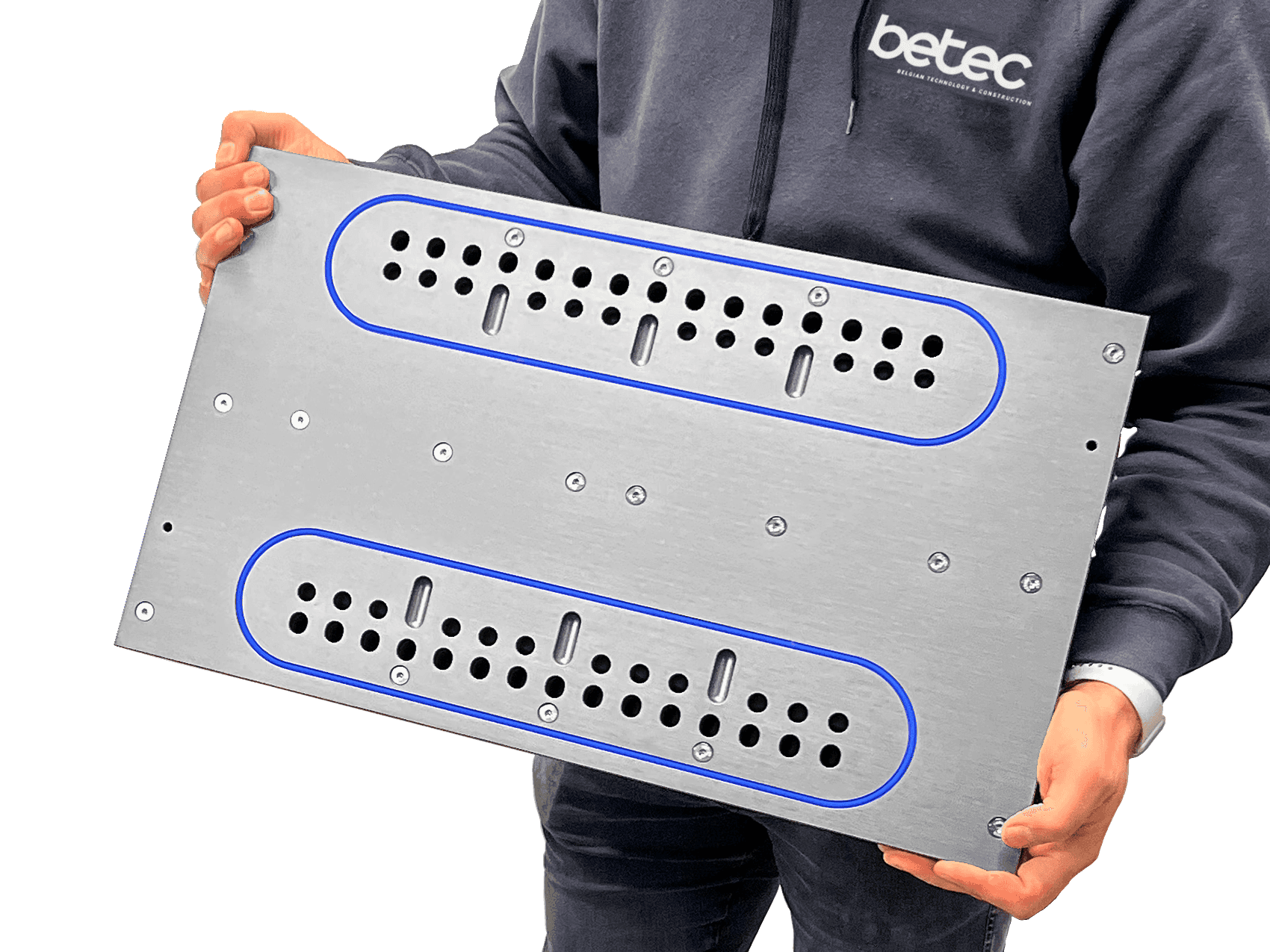

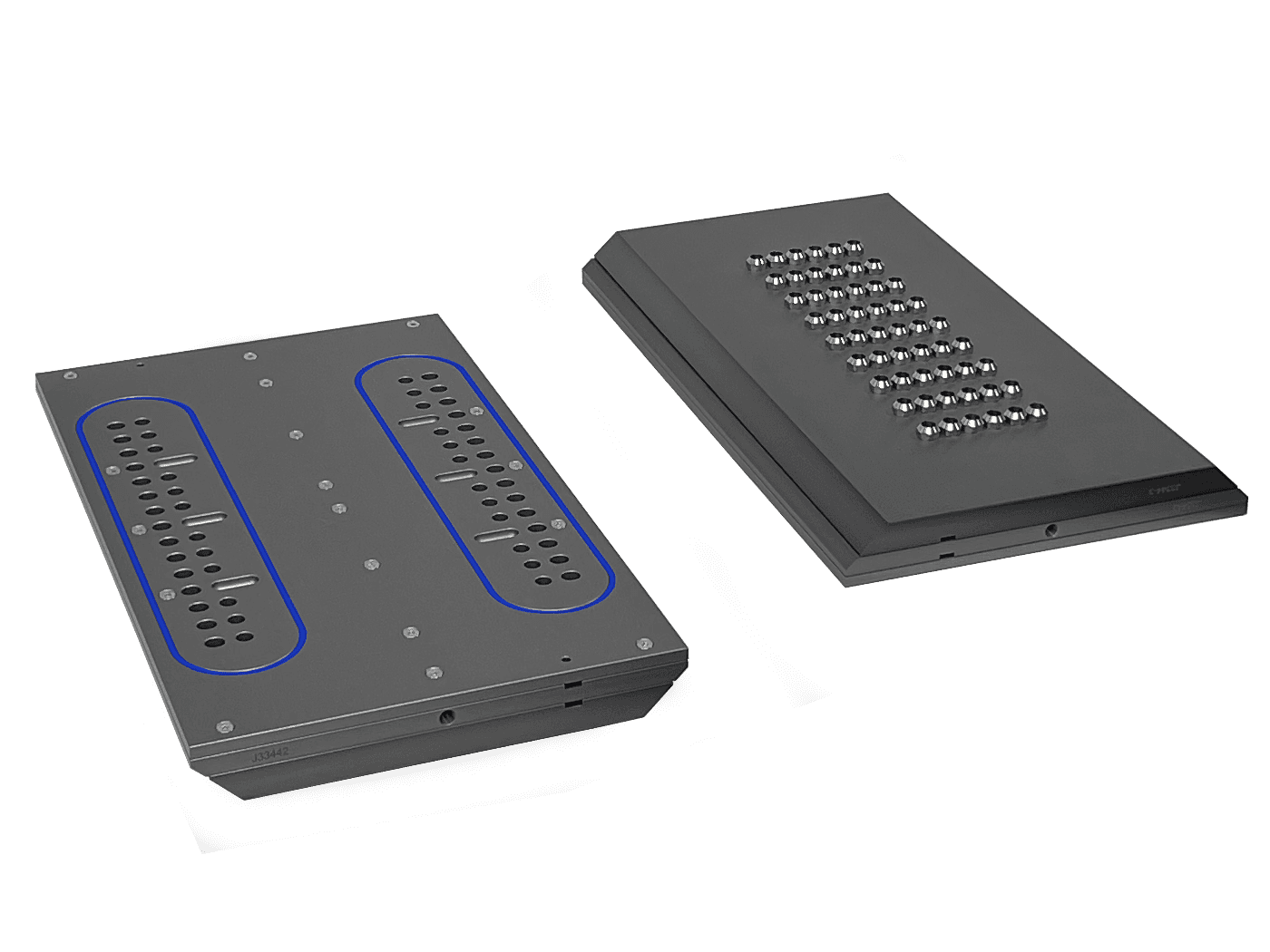

1.1 CMDH – Custom-Made Dosing Head

The Custom Made Dosing Head (CMDH) combines a universal dosing head with a custom-made base plate.

This system ensures optimal precision, flexibility, and hygiene.

How does the dosing head work?

- The head is connected to the tempering machine and receives chocolate via a pump or valve, depending on the configuration of the tempering machine.

- An internal distribution system splits the chocolate evenly to each outlet.

- The aluminium construction provides excellent heat conductivity, ensuring a constant chocolate temperature.

How does the base plate work?

On the underside, we mount a custom-made base plate, with drillings that exactly match the cavities of your polycarbonate mould.

The principle:

- the head distributes the chocolate internally

- the base plate guides the chocolate to the correct positions

- each stream is positioned exactly above the correct cavity

The base plate is quick to change, flat, and easy to clean. Mounting is carried out via snap-lock or screw connection, depending on your preference.

Why this system is so efficient

- only the base plate needs to be changed during product changeovers

- uniform chocolate distribution without pressure differences

- no waste or post-processing

- hygienic design

- fully custom-made:

- mould type

- mould dimensions

- drilling positions

- hole diameters

- flow characteristics

With a CMDH, you ensure that every mould — regardless of layout or complexity — is filled perfectly and evenly.

1.2 EAD – Easily Adjustable Dosing Head

The Easy Adjustable Dosing Head (EAD) is designed for moulds in which the cavities are positioned at different locations, such as hollow figures.

Advantages of the EAD:

- flexible tubes that are easy to adjust

- quickly adjustable without changing the dosing head

- extremely precise filling at the correct position

- electrically heated

- available with snap-lock or screw connection

Heating Options for CMDH & EAD

Standard: electric heating

- integrated heating elements

- controlled by the tempering machine

- perfect heat distribution thanks to the aluminium construction

Optional: water heating

- even more uniform temperature across the entire dosing head

- minimal temperature fluctuations

- significantly reduced risk of solidification or burning in hard-to-reach areas

- if required, BETEC designs a custom external water circuit

Thanks to these custom-made dosing heads, you not only work faster and more accurately, but also achieve fully reproducible production results — time after time, for every mould and every layout.

2. Dosing Heads for Filling Dosing Machines (Piston Systems)

These dosing heads are designed for dosing:

- ganache

- caramel

- praline

- cream fillings

- other semi-liquid products

Our dosing machines are equipped with pistons that can be activated or deactivated individually, allowing the machine to be flexibly adapted to different mould types and blister patterns. In combination with the correct dosing head, this ensures a perfect filling in the correct position every time.

Features:

- fully custom-made dosing head

- mounted underneath the machine’s main block

- quick changeover for product switches

- available with various hole patterns and outlet diameters

- complete configuration according to centre distances and mould layout

- standard water-heated

When centre distances vary only slightly, flexible nozzles can also be provided, eliminating the need to replace the entire dosing head for each changeover.

3. Dosing Heads for One-Shot Systems

BETEC designs fully custom-made dosing heads for:

- our own one-shot production lines

- one-shot machines from other manufacturers

Possible configurations

- simultaneous dosing of chocolate and filling in one shot

- double fillings (e.g. double-filled pralines)

- large flow channels for inclusions such as whole hazelnuts

- shut-off valves for controlled and clean outlet

- execution adapted to product viscosity and machine characteristics

Typical applications

- tablets with nuts or other inclusions

- pralines with one or multiple fillings

- products where chocolate and filling are dosed simultaneously

The design of each one-shot dosing head is always adapted to the technical limits and capabilities of the dosing machine used.

Compatibility with Other Brands

Thanks to our in-house engineering department, BETEC can design custom dosing heads, adapters, and base plates, ensuring full compatibility with machines from other manufacturers and a perfect match with your production requirements.

We work based on:

- technical drawings

- 3D models

- or on-site measurements carried out by our technicians

This approach allows existing or older production lines to be modernised or expanded with more efficient and precise dosing technology, without the need to replace the entire machine. Whether you want to dose tempered chocolate, fillings, or one-shot combinations, BETEC offers a dosing head for every application. With standard models, fully customised solutions, and compatibility with other brands, we deliver solutions that meet high standards in terms of precision, hygiene, flexibility, and reliability.

For more targeted information or a specific application, feel free to contact us via the link below. We will be happy to discuss together which dosing head best suits your machine and product.