Product

Back

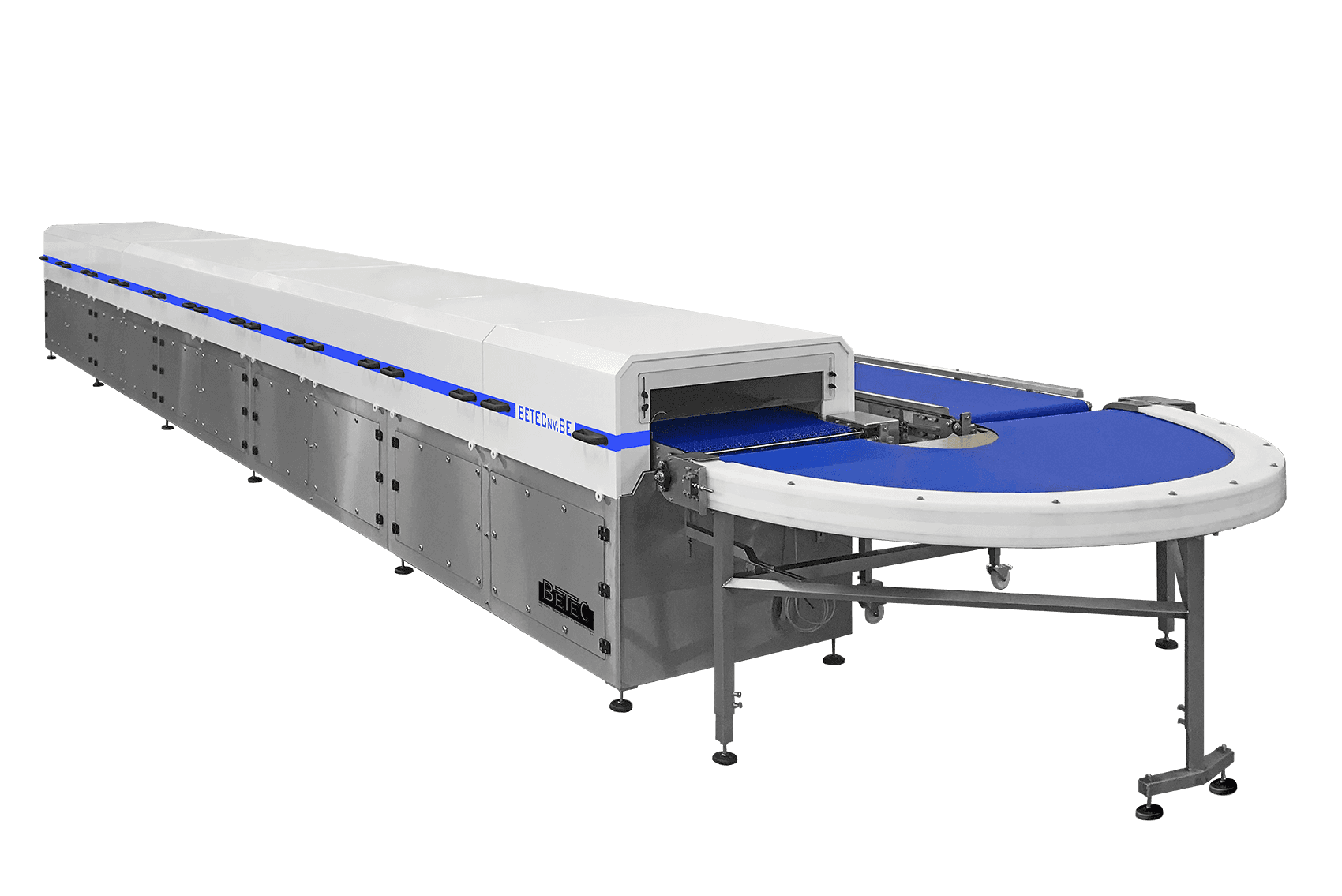

CL 600 + MB 120 + TK 100

Moulding line for solid products with or without ingredients

This trio is guaranteed to increase and speed up the production capacity of your solid products with or without ingredients. The TK 100 tempering kettle melts and tempers your big chocolate volumes and pumps them to the MB 120 wheel machine.

To this you add your ingredients such as nuts, seeds, aromas, flavours and/or dyes. Have the chocolate and the ingredients been mixed into a homogenous mass? The CL 600 pushes the polycarbonate moulds through the filling and scraping station and over the trembler.

The MB 120 is the only machine in this line you need to completely clean. It has no pump or pipes which makes cleaning a piece of cake.

The moulding line for solid products with ingredients comprises

- CL 600 moulding line

- MB 120 wheel machine

- TK 100 tempering kettle for batch tempering

Features:

- has an electrically heated melting container of 120 kg for bigger volumes

- is equipped with an overflow-filling station, including scraping station and heated scrapers

- is easy to operate using the colour touchscreen

- is made from standard components

- is made of AISI 304 stainless steel

- meets CE standards

.png&w=1500&q=60)

.png&w=1500&q=60)

.png&w=1920&q=60)

.png&w=1920&q=60)