Product

Back

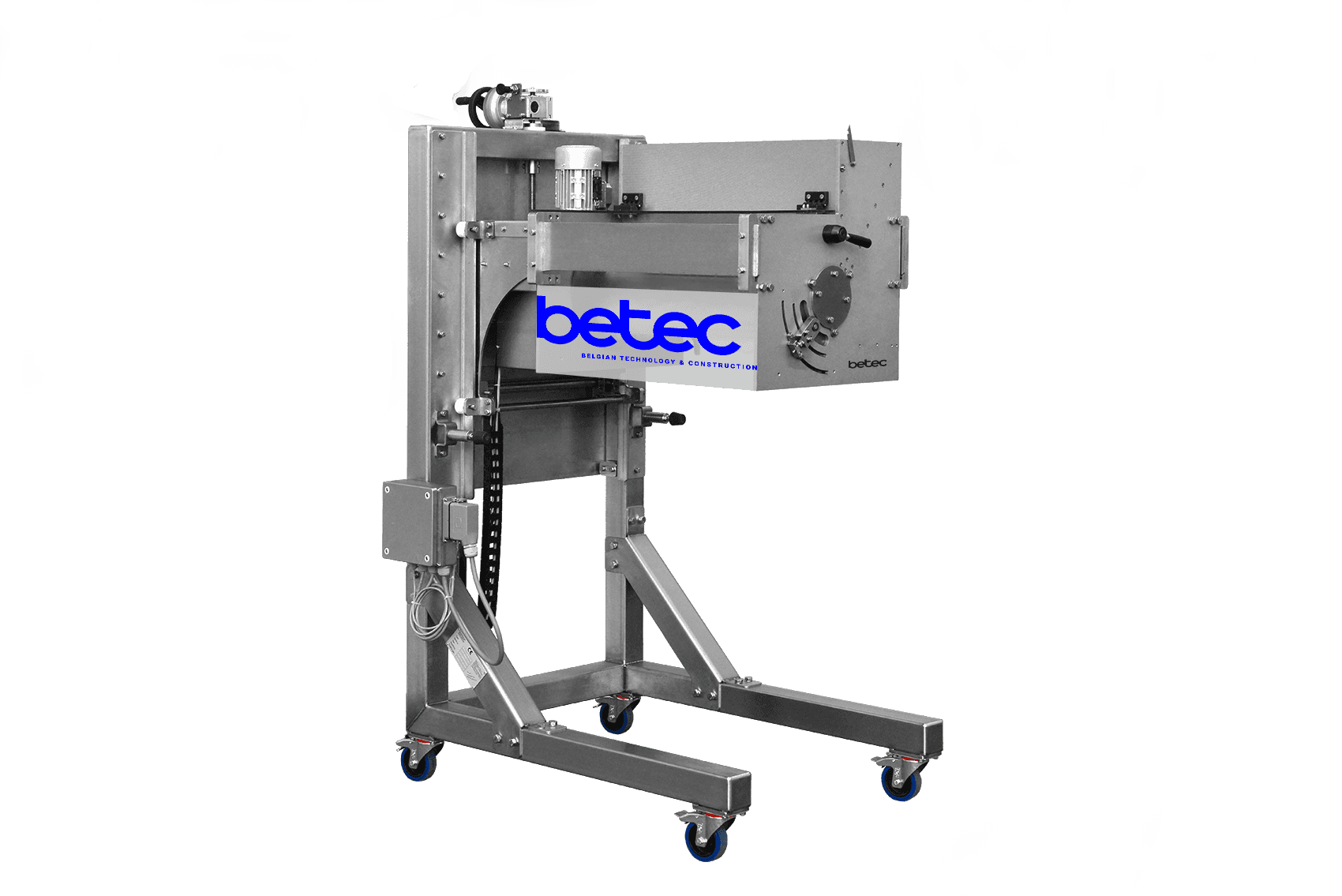

GDC + ATE 120-450 + KT

Enrobing line

Whether you want to enrobe biscuits, waffles, protein bars, truffles, fruit or other fillings, our enrober does it with extreme precision. The automatic cutting machine slices the ganache and automatically places it on the input of the tempering and enrobing machine. Nobody wants runny, badly crystallised products. That's why the custom built cooling tunnel cools them immediately to the right temperature. Yes, this enrobing line is a must-have for every chocolate professional looking for efficiency and the highest quality.

Do you work with real chocolate instead of compounds? Then get an internal or external tempering system. BETEC builds custom-made lines, from melting tank to packing belt.

The enrobing line consisting of a cutting machine, tempering and enrobing machine, and cooling tunnel

Features:

- consists of an enrober custom-made to your application with:

- a removable infeed belt

- an enrober belt to enrobe your products on the bottom side, completely or partially

- an adjustable chocolate bridge to create a chocolate curtain

- an adjustable blow off ventilator

- a trembling system

- licking rollers

- an adjustable heated rod-detailer

- consists of a cooling tunnel with:

- radiation or convection cooling

- a cooled bottom plate is optional

- has a hygienic design

- is operated with the PLC colour touchscreen

- ganache cutting machine

Options:

- decorator for granulate and/or chocolate

- melting tank

- ganache pouring table

- inliner

- packing belt

- ganache table

.png&w=1920&q=60)

.png&w=1920&q=60)

.png&w=1920&q=60)

(8).png&w=1920&q=60)

(8).png&w=1920&q=60)