Product

ML 600

Moulding line for hollow moulds

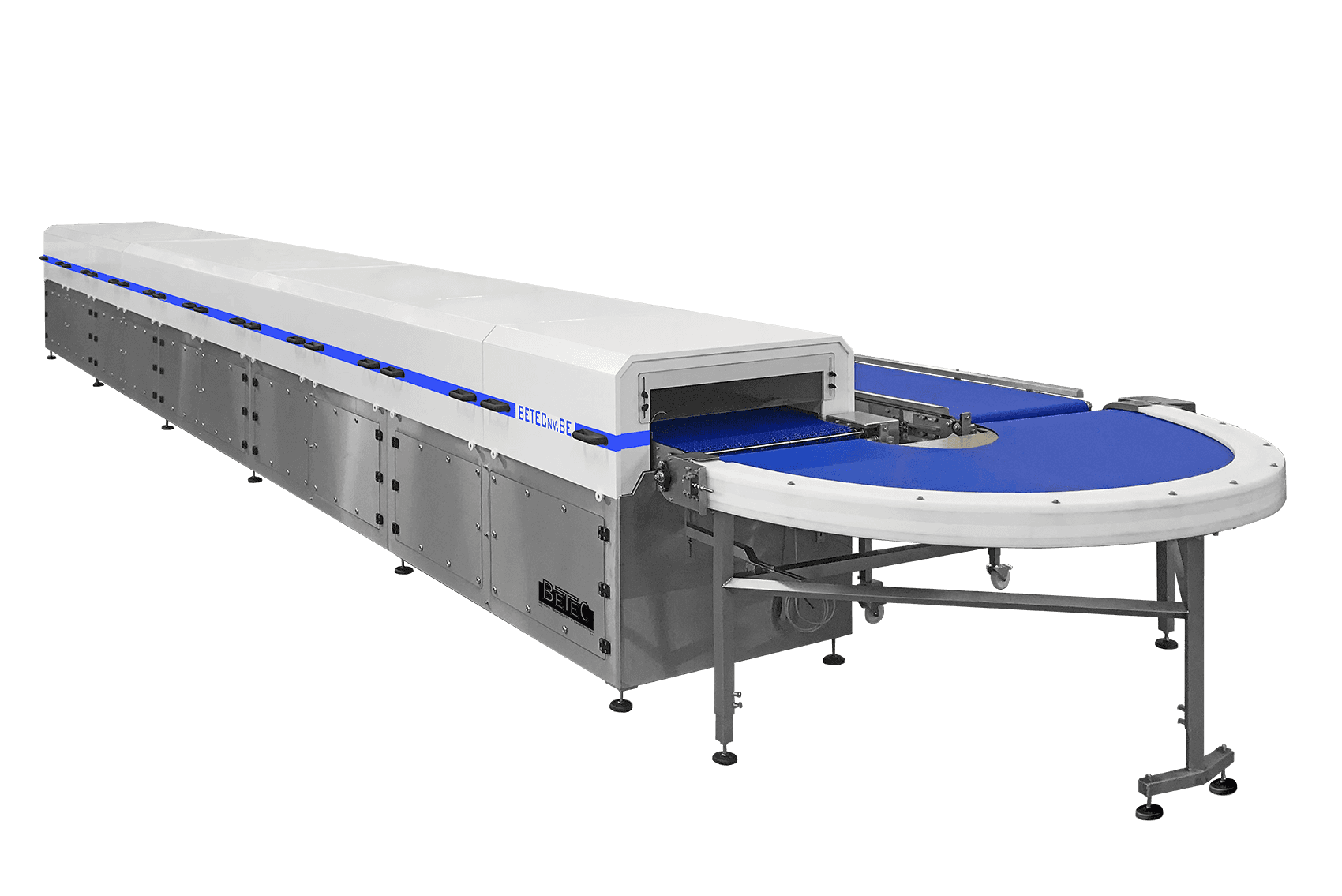

Just like the CL moulding line the ML line fills your moulds, levels and trembles them. The difference? The ML line allows you to create hollow forms that you then fill with your desired filling. In other words, the ideal machine for filled chocolate bars, chocolates or pralines. The ML 600 has an average push-through speed of 600 moulds an hour.

After the moulds have been filled, levelled and trembled, the ML moulding line turns 180 degrees to empty the moulds again. They go to the second trembling feeder, which leaves a layer of chocolate in the mould. You determine the thickness by setting the trembling intensity on the colour touchscreen. When the moulds have set and cooled, they can be filled. Ready? Send them through the ML-line a second time to seal the chocolate mould.

The moulding line for filled chocolate bars, chocolates or pralines ML 600

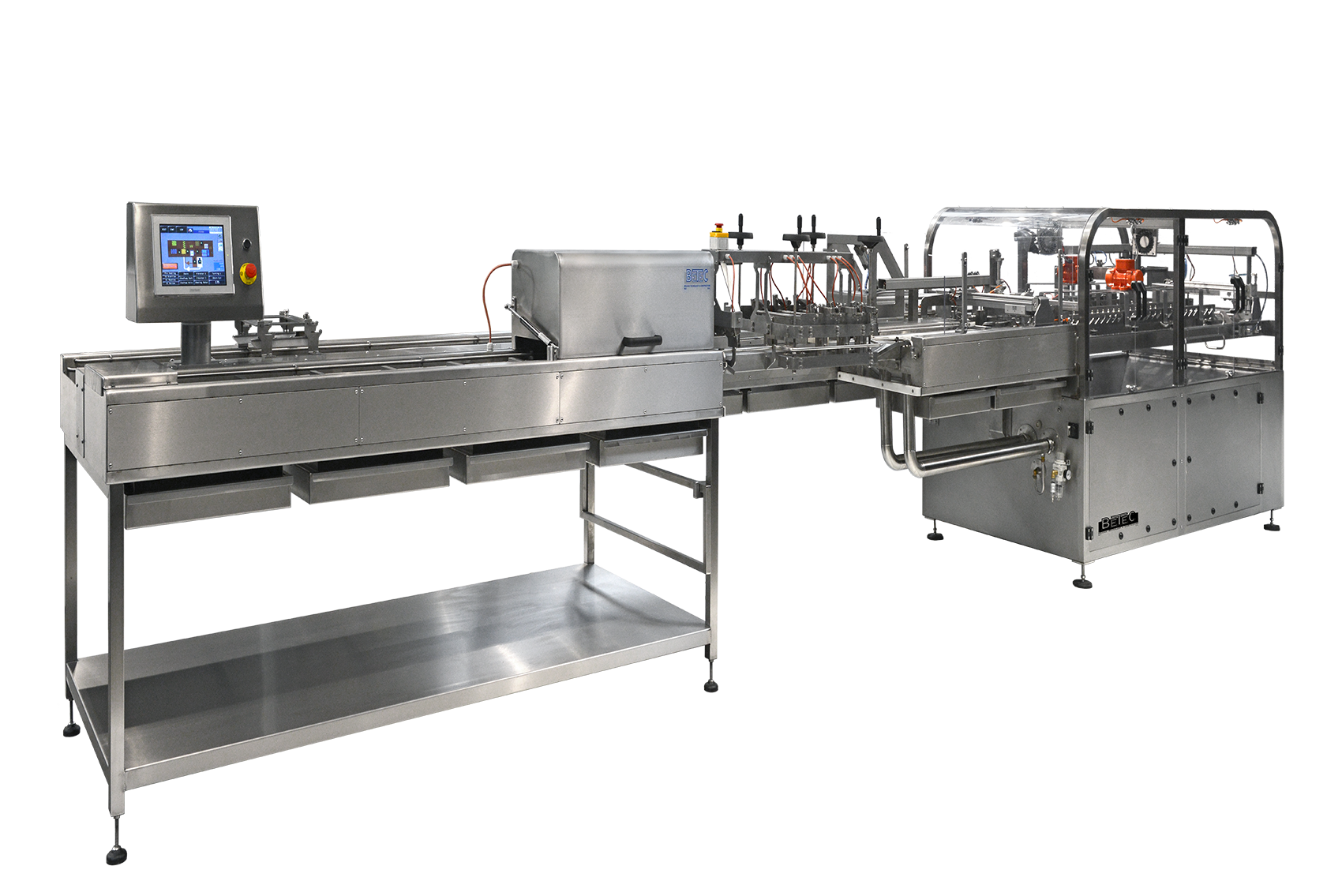

Features:

- simplify your production process and increase the capacity

- can be assembled based on your application and budget

- are preheated preheating system

- are equipped with an overflow-filling station with a scraping station with heated scrapers

- work with three different mould sizes: 135, 175 and 205 mm width

- are easy to operate using the colour touchscreen

- consist of standard components

- are made of AISI 304 stainless steel

- have a three-phase 380 V 50/60 Hz connection

Options:

- mould destacker

- mould tilting system to correctly reposition moulds stacked upside down

- mould cleaning system with or without UV cleaning

- dosing system instead of enrobing and scraping

- dosing system for fillings

- one schot dosing system

- shortcut system

- integrated vertical cooling tunnel with different temperatures

- automatic demoulding system

- extra turn station(s)

- automatic mould return

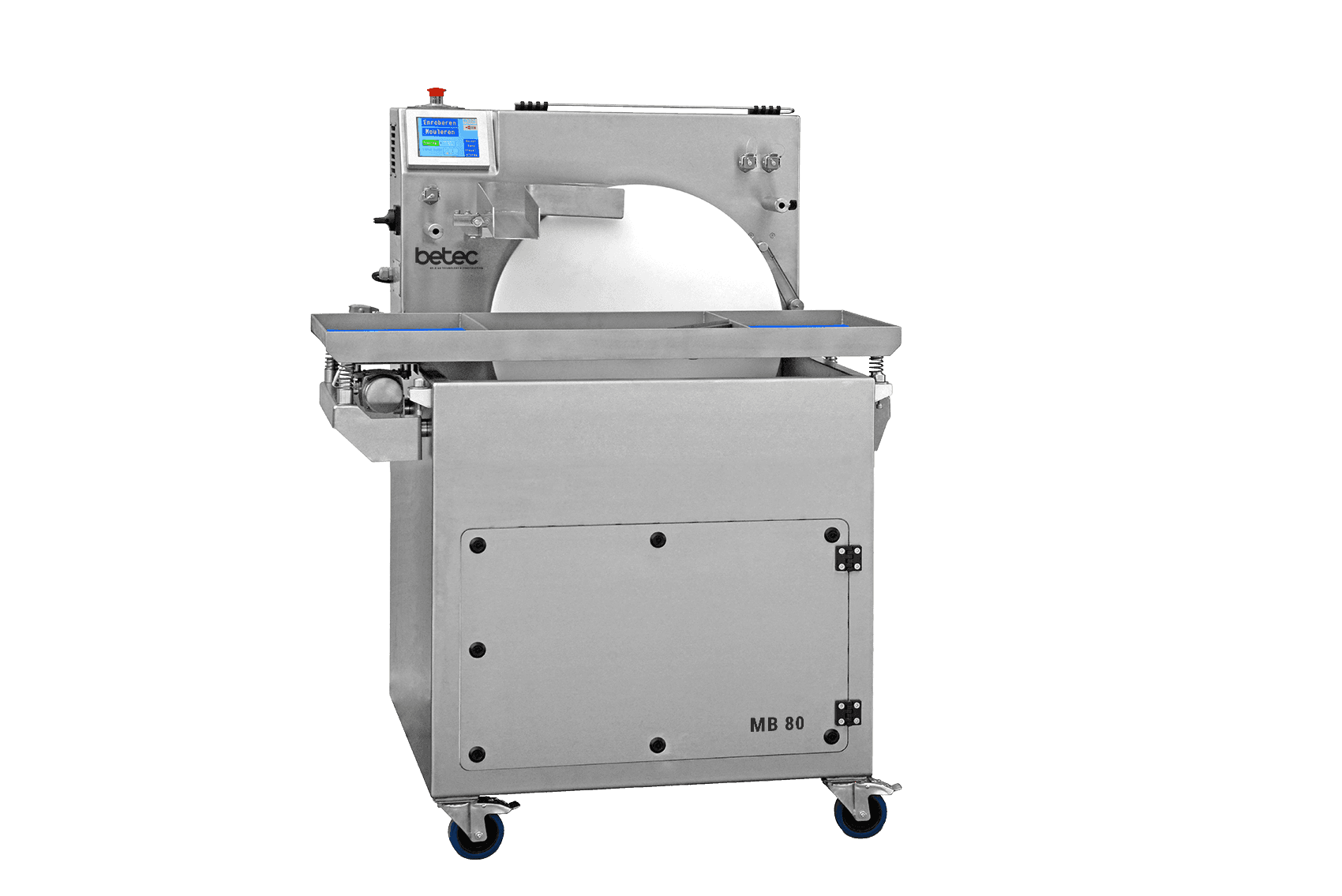

.png&w=1500&q=60)

.png&w=1920&q=60)

.png&w=1920&q=60)